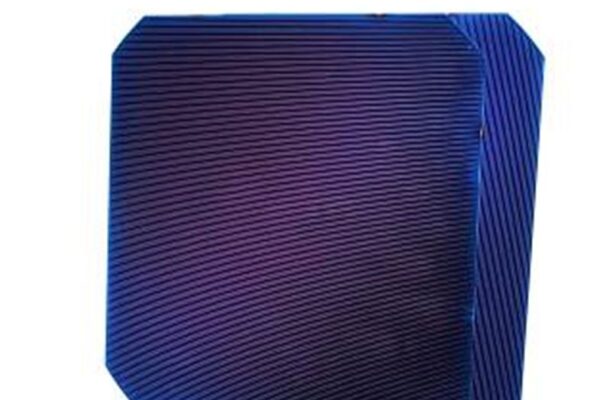

Bifacial n-PERT solar cell boasts 22.8% front-side efficiency

Featuring a transparent backside and comparable front- and back contact schemes, bifacial solar cells capture light on both sides of the cell. As a result, they also profit from indirect light, light reflected by the ground and buildings, diffuse light on overcast days, and even direct light at sunrise or sunset, incident on their rear surface.

Used bifacially under standard front illuminations conditions in conjunction with an additional 0.15 sun rear illumination, these cells can produce the equivalent energy of 26.2 percent monofacial cells. At module level, the newly developed bifacial cell technology has a projected low cost-of-ownership under 0.30 $/Wp which further reduces the levelized cost of electricity (LCOE) of large photovoltaic (PV) installations.

Tests indicate that, over the course of their lifetime, such cells may generate 10 to 40% more electricity than traditional monofacial cells (this proportion depends on their bifaciality, the PV installation properties and the reflection of the location). This may result in an estimated LCOE reduction for PV installations of 10 up to 30 percent.

with up to 22.8% front-side efficiency and near 100%

bifaciality

IMEC’s bifacial n-type PERT cells (Bi-PERT) feature thin and narrow (20µm) nickel-silver plated fingers on both the n+ and p+ side of the cell. The cells’ contacts were fabricated in a patented process of simultaneous plating both cell sides. This cell plating is performed on cassette level (simultaneous plating on a full cassette of wafers in a chemical bath) without the need for an electrical contact to be made to the substrates.

This resulted in a solar cell batch with an average conversion efficiency of 22.4 percent, with the best cell topping 22.8 percent (a record for this type of cell). The measurements were made using only front side illumination and a non-reflective chuck.

Commenting on the low cost of ownership, Filip Duerinckx principal engineer at IMEC explained it results from the low-cost patented metallization, the fine finger contacts, and the potential of multi-wire interconnection schemes.

“Especially the very limited use of silver compared to traditional screen-printed bifacial cells has a beneficial impact on the cost. As for the bifacial aspect: our cells have a near 100 percent bifaciality, which maximizes the bifacial gain. We are now working to demonstrate this technology on full 60-cell modules with wire interconnection, which we expect will reveal the full potential of this promising bifacial technology on an industrial level”, Duerinckx said.

IMEC – www.imec-int.com.

EnergyVille – www.energyville.be

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News