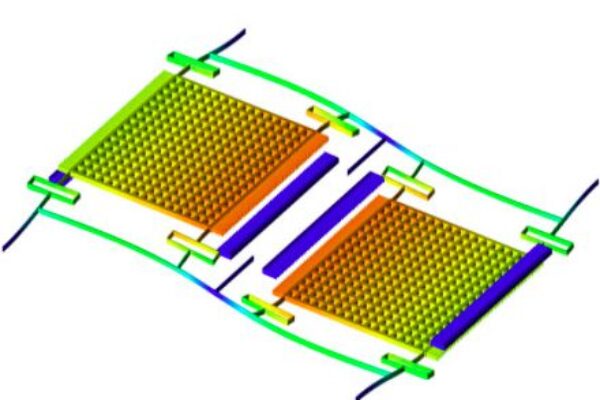

The upgrade includes enablement for MEMS process design kits (PDKs) and links to analog electronic design suites such as Virtuoso from Cadence Design Systems Inc. Steve Breit, vice president of engineering at Coventor said the company had worked with MEMS foundry X-Fab Semiconductor Foundries AG as a lead partner for the enhancements in v6.0 of MEMS+.

One of the key developments is that MEMS+ 6.0 users can create a technology-defined component library that imposes technology constraints and design rules during design entry, resulting in a “correct-by-construction” methodology. This new approach reduces design errors and enables MEMS foundries to offer MEMS Process Design Kits (PDKs) to fabless MEMS designers. Both parties benefit with submitted designs having fewer errors, and ultimately fewer design spins and fab cycles required to bring new and derivative products to market.

This ability to support PDKs and the customization of sensors and packaging is likely to be of particular value in multi-die systems such as wireless sensor nodes (WSNs) being deployed within the Internet of Things Breit told eeNews Europe.

We have collaborated with Coventor in defining the requirements for MEMS PDKs for MEMS+” said Joerg Doblaski, director of design support at X-Fab Semiconductor Foundries, in a statement issued by Coventor.

MEMS+ v6.0 allows the creation of a library of higher order finite element models along with technology constraints and materials properties. These can then snap together in a 3D user interface. MEMS+ v6.0 also includes a second-generation model reduction capability with export to MathWorks Simulink as well as the Verilog-A format. The resulting reduced-order models (ROMs) simulate nearly as fast as hand-crafted models, but are far more accurate. This enables system and IC designers to include accurate, non-linear MEMS device models in their system- and circuit-level simulations. For the second generation, Coventor has greatly simplified the inputs for model reduction and automatically includes the key dynamic and electrostatic non-linear effects present in capacitive motion sensors such as accelerometers and gyroscopes. ROMs can be provided to partners without revealing critical design IP.

Additional advances in MEMS+ 6.0 include:

Support for design hierarchy

Refined support for including packaging effects in thermal stability analysis of sensors.

Improved modeling of devices that rely on piezoelectric effects for sensing.

An expanded Matlab scripting interface that now allows design entry as well as simulation control.

Related links and articles:

News articles:

IMEC, Coventor model 10nm, 7nm processes

Coventor upgrades MEMS design software

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News