Crossbar ReRAM in production at SMIC

The Crossbar ReRAM for embedded non-volatile memory applications is in production at partner foundry Semiconductor Manufacturing International Corp. (SMIC) using a 40nm CMOS process and is sampling to SMIC (Shanghai, China) customers, according to Sylvain Dubois, vice president of strategic marketing and business development.

Dubois told eeNews Europe that not only is 40nm ReRAM in production but that production on 28nm CMOS would follow soon. Dubois defined that to mean the first half of 2017 but he declined to say whether that would be with SMIC or another foundry.

Founded in 2010 Crossbar is well-backed with more than $80 million raised to date including support from the China-based venture capital firm Northern Light Venture Capital. It is pursuing an IP licensing business model.

Crossbar, is one of many companies racing to develop a non-volatile memory technology that could replace flash memory and scale to 28nm and beyond. ReRAM has looked a likely candidate after the failure of phase change memory to succeed in the market place. But there are numerous versions of ReRAM technology and in many cases a deep understanding of the physics behind switching and failure modes has been missing. Some have even indicated that Magnetic RAM could be the non-volatile memory to win out at the 28nm node (see MRAM is leading embedded NVM race, says IMEC researcher and IEDM: Magnetic RAM debuts as 28nm embedded NVM).

Another rival is non-volatile memory based on a layer of carbon nanotubes in a matrix as offered by Nantero Inc. (Woburn, Mass.) which has licensed its technology to fabless chip company Fujitsu Semiconductor and to foundry Mie Fujitsu Semiconductor for use at 55nm and with 40nm to follow (see Fujitsu is licensee of Nantero’s carbon-nanotube RAM).

Next: Silver filaments

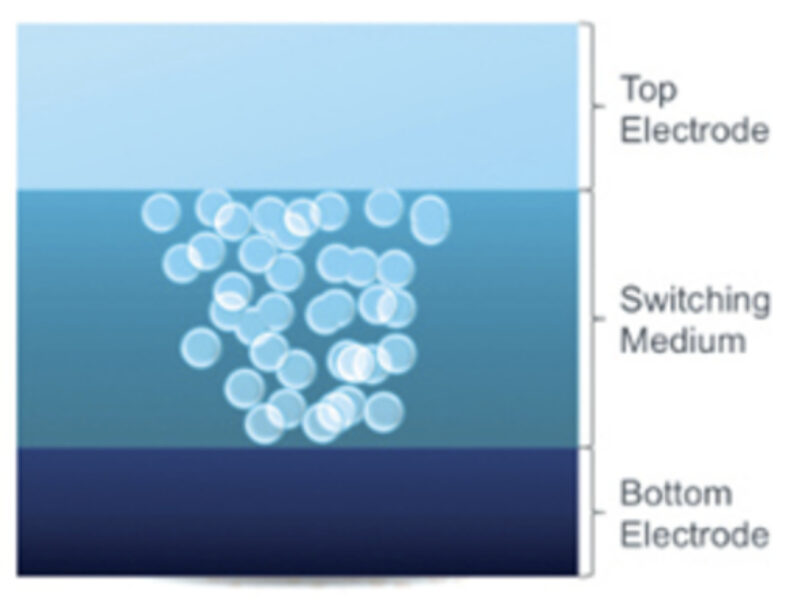

Crossbar’s ReRAM technology is based on non-conductive amorphous silicon (a-Si) as the host material for a metallic filament formation. A top electrode is made of silver which provides the metallic ions for the filament. The principle of operation is that a writing voltage causes silver ions to migrate through the silicon to form a filament that eventually can connect the top and bottom electrodes. A reverse voltage causes the ions to move and break the connection. Lower voltages can be used to “read” the connection as a 1 or 0.

There are some similarities to the programmable metallization cell technology of Adesto Technologies Corp. and others and being brought to market under the term conductive bridging RAM or CBRAM.

Dubois stated that Crossbar ReRAM is performing well and licensees are receiving samples from SMIC to enable them to develop SoCs containing the standard hard macro which is an 8Mbit memory, or to develop their own hard macro NVMs for inclusion in their SoCs. Typical application include memory for energy-efficient microcontrollers used in IoT, smart sensors or wearables.

“Some applications need 16Mbit and more and some don’t need that. We are working on larger macros but we also let customers develop ReRAM macros,” said Dubois.

The ReRAM is already showing considerable advantages over flash memory including read latencies 20ns and write latencies of 12ns, which compare with millisecond latencies for flash memory, Dubois said. “We don’t have block erase so a single byte can be rewritten,” he added. As to endurance Dubois said Crossbar guarantees 100k read-write cycles. “For these applications 100k is the target although we are pushing for higher endurance,” said Dubois.

Crossbar is pursuing a twin-track business strategy working on both ReRAM for embedded non-volatile and also as a technology developer of high capacity stand-alone memories. The embedded NVM is about a year ahead in terms of maturity although at the 2016 Flash Memory Summit and at 2017’s Consumer Electronics Show Crossbar has been demonstrating its ability to do cross-point arrays with a select element.

Next: Scaling and 3D capable

Crossbar also claims the ability to do 3D stacking of its dense cross-point memory arrays, which together the ability to scale below 10nm and to store multiple bits per cell, would allow high capacity non-volatile terabyte memories on a single die.

Dubois said Crossbar was working with a company or companies to create high-capacity discrete ReRAM and that it would use a licensing business model there too. He declined to name any partners or licensees.

Previously Crossbar had stated that it would develop stand-alone memories under its own brand to replace NOR flash in code storage and NAND flash in data storage. “To enter the market has to be through strong strategic alliances,” said Dubois. “We want to be the ARM of memory.”

Dubois said that none of Crossbar’s customers is in commercial production themselves with ICs with embedded ReRAM but now that they have samples from SMIC that point was approaching quickly. “This is a critical phase for the company and the market. We have to prove reliable.”

Related links and articles:

News articles:

Updated: Crossbar signs SMIC as embedded ReRAM partner

MRAM is leading embedded NVM race, says IMEC researcher

Discrete ReRAM goes into mass production

Nantero takes funding above $110 million

IEDM: Magnetic RAM debuts as 28nm embedded NVM

Fujitsu is licensee of Nantero’s carbon-nanotube RAM

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News