Foundation fieldbus right to the point

For this implementation a couple of individual demands had to be fulfilled, restricting possible implementation approaches. One of BIFFI’s key products is the intelligent electric actuator ICON2000, which is mainly used for refineries, tank farms, off-shore oil platforms, and oil pipelines. For this electric valve actuator a new version has been released recently, which is introducing a new philosophy in the electronic cards construction. The basic idea here is to integrate all the main functionality in the basis card and to use additional modules for advanced improvements and additional functionality. For instance, various modules are supported to provide access to the major fieldbuses available on the market. This way the actuator can be used together with proprietary as well as with non-proprietary bus products, which allows the overall system to be exactly tailored to the user’s needs for operation, control, setting and maintenance.

Figure 1: The Foundation fieldbus version of the BIFFI ICON2000 actuator uses the standard hardware design. The Foundation fieldbus module is exchanging data with the ICON2000 basis card as well as the Fieldbus Kit for fieldbus access.

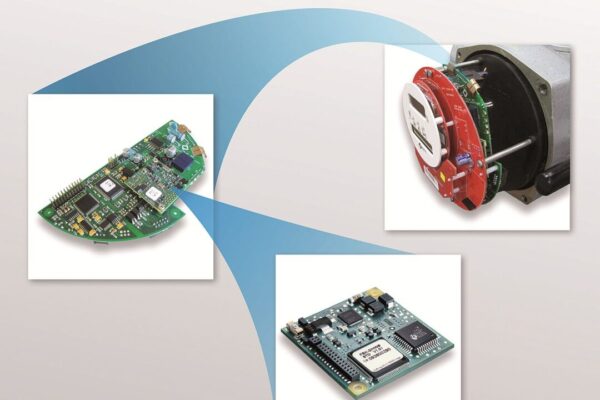

Following the market requirements, BIFFI decided also to implement the Foundation fieldbus H1 communication protocol for the ICON2000 actuator. Here BIFFI was looking for a solution, which could be implemented without big impact within the overall ICON2000 design, which fulfils the individual market requirements and which provides a good performance. After a detailed evaluation BIFFI decided to make use of Softing’s Fieldbus Kit product for this implementation. This product combines the communication hardware as well as the required firmware for implementing Foundation fieldbus H1 field devices and has proven to ease and shorten the fieldbus implementation process within many field device projects. When following this approach, a device manufacturer does not have to learn and understand the fieldbus know-how in detail, but can concentrate on integrating the Fieldbus Kit into the device application.

As a result of the Fieldbus Kit evaluation, BIFFI found out that, due to its small footprint, this product can be integrated directly as a plug-in card into the ICON2000 actuator with its Foundation fieldbus module. Thus this approach significantly reduced the fieldbus implementation effort and cost at BIFFI’s side, for instance by eliminating the need to develop an own Foundation fieldbus H1 hardware or by avoiding the need to port the Foundation fieldbus H1 protocol stack to a specific BIFFI target platform.

The complete BIFFI Foundation fieldbus H1 implementation is based on a two processor solution: While the application is running on the ICON2000 Foundation fieldbus module, the Foundation fieldbus communication is performed by the Fieldbus Kit processor. As a consequence of this distribution of the complete fieldbus implementation onto two separate processors, certain means are necessary to assure the required data exchange. Here on one hand a high-speed communication channel is used, while on the other hand the synchronization between the two processors is performed via the serial Modbus protocol.

Figure 2: The BIFFI ICON2000 actuator also is available with a Foundation fieldbus H1 interface.

The data exchange of the ICON2000 actuator has been realized based on a quite sophisticated strategy, which is different for read and write requests. All read requests are handled according to an automaton, which switches between reading/writing one item of cyclic data (process data) and reading one item of acyclic data (Resource/Transducer block parameter) before data processing according to the configured Function Block is performed. The transfer of the real process values to the individual Modbus registers is performed by the Modbus master of the Fieldbus Kit when executing the cyclic list.

On the other hand, writing of data is performed upon an external request, which then triggers sending a Modbus request from the ICON2000 actuator to the Fieldbus Kit process. As Foundation fieldbus is working based on a 4 Bytes Float datatype while Modbus is using 16 Bit registers, an adaptation of the individual values including a swapping of the high and low bytes has been necessary for all read and write operations. In summary, the BIFFI Fieldbus Kit implementation is quite a complex one, while this platform in general allows to implement Foundation fieldbus H1 for a wide range of various field devices.

The complete application development has been performed by BIFFI. For easing this task special templates were provided by Softing, which then have been individually extended by BIFFI. For instance, the application development included the definition of the various Resource/Transducer Block parameters, which refer to the individual ICON2000 parameters. As part of the Resource/Transducer Block the individual parameters are stored within a structure. In addition the status handling has been defined by BIFFI by associating error texts to the individual ICON2000 flags. Also the definition of the Device Description file has been a task performed by BIFFI. For all these tasks Softing provided individual support to make sure that the results met the Foundation fieldbus requirements. For instance Softing checked the Resource/Transducer Block definition as entered into the appropriate Excel template or assisted in creating, testing and debugging the Device Description file using the Fieldbus Foundation Tokenizer.

As a result a quite complex application has been implemented, which is based on a channel matrix. This matrix defines the individual channels, which are supported by the various Foundation fieldbus Function Blocks together with the impact to the channels of other Function Blocks when selecting an individual channel. In addition, the ICON2000 can operate in two modes, in digital mode (OPEN, CLOSE, …) or in analog mode (given setpoint).

While BIFFI was working on the application, Softing had to adapt the Fieldbus Kit Foundation fieldbus firmware in order to fulfil the individual BIFFI requirements. These adaptations primarily referred to the number of Virtual Communication Relationships (VCRs), which were necessary for the transfer of data between Foundation fieldbus field devices. While the standard Softing firmware supports 24 VCRs, covering the majority of all field device applications, the BIFFI application required a high number of Discrete Output, Discrete Input, Analog Output, Analog Input, and PID Function Blocks and I/Os, resulting in the need to support a higher number of VCRs. Thus Softing extended the VCR list, which is kept in the EEPROM of the Fieldbus Kit and adapted the associated management according to the BIFFI requirements. In addition Softing also implemented a fast Function Block execution as required by the ICON2000 firmware.

As the Fieldbus Kit is an off-the shelf and proven solution for the rapid development of Foundation fieldbus H1 field devices, Softing already has successfully performed the Physical Layer Test as well as the Conformance Test as defined by the Fieldbus Foundation for this product. Thus these tests do not have to be repeated for each individual field device including the Fieldbus Kit. Rather the certificates of these tests can be used when performing the Interoperability Test, which defines the final step of field device certification at the Fieldbus Foundation. Thus, at the end of the implementation project, BIFFI benefited from the already available Fieldbus Kit certificates and was able to reach a smooth and fast certification of the ICON2000 actuator Of course, this approach also results in a significant reduction of the related certification costs.

Figure 3: The Softing Fieldbus Kit product is an off-the shelf and proven solution for the rapid development of Foundation fieldbus H1 field devices.

About the author

Georg Süss is Marketing Communications Manager for Softing Industrial Automation – www.softing-ia.com – he can be reached at georg.suess@softing.com

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News