Zero-Configuration Platform for Wireless Sensing & Actuation

Introduction

Industrial Internet of Things applications, such as smart factories or cities, demand large numbers of wireless embedded devices equipped with a variety of sensors and actuators. These devices are often expected to operate over long periods in time in harsh RF environments, while periodically capturing environmental or industrial process data. Unfortunately, the current generation of industrial sensing solutions requires significant efforts in terms of development, installation, integration, and management to enable robust IoT systems at scale. Most users therefore struggle with this complexity and its associated costs, and consequently fail to maximize the return on their investment. Hence, in order to drastically reduce the total cost of ownership for industrial IoT scenarios, a solution is needed that combines easy integration of third-party sensing peripherals with existing applications, reliable, secure and ultra-low power networking, and online cloud services for collecting and storing sensor data.

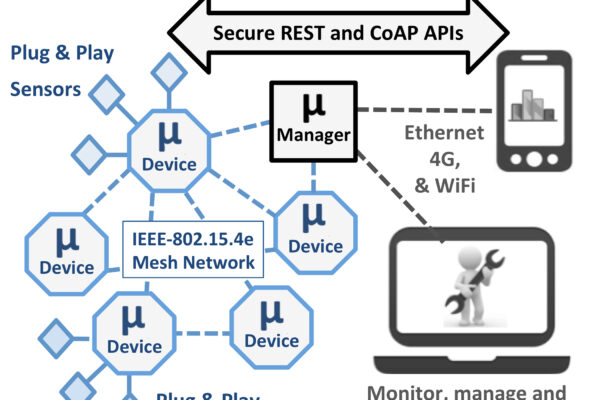

This article describes the MicroPnP platform (Figure 1), the standards-compliant low-power Sensing-as-a-Service solution by VersaSense, which realizes true Plug-and-Play integration of sensing and actuation peripherals, scalable 24/7 monitoring and control of devices across different sites, and secure end-to-end communication. In contrast to traditional industrial IoT solutions, MicroPnP adopts a radically different approach to eliminate development and management complexities and hence drastically lower the total cost of ownership of industrial IoT systems.

True plug-and-play integration of peripherals is realized by means of passive electrical components that are used as efficient mechanism to detect and identify newly connected sensing or actuation peripherals over time. MicroPnP’s software stack, in turn, implements solutions for secure device commissioning, automatic over-the-air firmware updates and APIs for integrating sensed peripheral data with online cloud services. Finally, MicroPnP employs SmartMesh IP from Linear Technology, providing best-in-class wireless mesh networking technology, achieving over 99.999% network reliability even in harsh RF environments, while offering a decade of battery lifetime.

MicroPnP is the result of a decade of academic research and has been awarded in the 2015 international IPSO Challenge, an annual global competition organized by the IPSO alliance. The IPSO alliance actively promotes the use of open protocols and standards (e.g. the Internet Protocol (IP) and associated IETF protocols) for building the next generation of Smart Objects. Today, MicroPnP is being successfully applied in industry scenarios across the world, ranging from data center monitoring, precision livestock farming and monitoring in the oil and gas industry.

The MicroPnP Solution in a Nutshell

MicroPnP offers a coherent hardware and software toolkit that combines automated detection and configuration of embedded sensing peripherals into the IoT, with extreme wireless networking reliability and battery lifetime. Key differentiators include:

1) Zero-configuration Plug-and-Play peripheral integration. MicroPnP automatically identifies all connected embedded sensing and actuation peripherals and installs their corresponding device driver software. The approach relies on low-power passive electrical components and identifying a peripheral consumes 1 million times less power than traditional solutions like USB or FireWire. Moreover, the approach is very cheap and flexible, allowing any existing IoT sensor or actuator to be immediately repackaged as a MicroPnP-peripheral.

2) Automatic software installation and maintenance. Once a peripheral is plugged in into a MicroPnP device, all corresponding device driver software is automatically requested to the network gateway and subsequently installed over-the-air. From this moment on, the peripheral is fully functional and available for remote interaction by end-users. To further accommodate application developers, the network manager exposes RESTful APIs to query all devices and directly push sensor data into the cloud.

3) Ultra-reliable mesh networking at extremely low power. At the network level, MicroPnP integrates with Linear Technology’s SmartMesh IP embedded wireless mesh networking. SmartMesh IP is a commercial implementation of the Time slotted Channel Hopping (TSCH) mode of IEEE 802.15.4e, and combines its performance with meshing capabilities and the ease of use of IPv6. To ensure high data reliability in the face of RF interference, multi-path fading, and other environmental factors, TSCH combines a reservation-based Time Division Multiple Access (TDMA) scheme with channel hopping. By continuously monitoring the state of the network, and optimizing the TSCH schedule for every device, a MicroPnP network can run autonomously for a decade on a single pair of AA-batteries.

4) Avoiding vendor lock-in through open standards and protocols: the MicroPnP protocol stack on every device is fully compliant to IEEE, IETF and IPSO standards, and therefore easily integrates with third-party solutions. At the link layer, SmartMesh IP uses IEEE 802.15.4e TSCH, while the traditional IPv6-ready IoT ‘upper stack’ is composed of IETF-6LoWPAN, UDP, and CoAP. In addition, every MicroPnP peripheral adopts the IPSO data model that tackles the interoperability problem between heterogeneous devices and third-party applications. The IPSO data model defines a common Object Model, consisting of a URL template and standardized set of data types that enables application software to meaningfully interact with devices, including software in other devices.

5) Effortless application development and integration. Finally, a suite of software libraries (available in JavaScript, Java, and NodeJS) provide programmatic access MicroPnP-enabled networks, while allowing for the establishment of NAT-proof connections between end-user applications and MicroPnP devices. As these libraries integrate directly with the MicroPnP software stack on every device, network gateway, and cloud element, they empower everyone to build complete IoT systems in minutes.

The MicroPnP Model in Practice

The typical model of installing and operating a network of MicroPnP devices is as follows :

- Integration of sensing and actuation peripherals: Once a sensing or actuation peripheral has been plugged in, the MicroPnP application board automatically detects and derives its type. Afterwards, it requests a suitable driver to the managing entity running in the cloud.

- Peripheral driver installation and network integration: Whenever the managing entity receives a driver installation request, it automatically downloads and installs the device driver on the requesting device. Upon completion, the peripheral is made available for use within the network.

- Programmatic access and management: Finally, the set of reusable software libraries drastically eliminates development costs. These libraries provide global bidirectional access between remote clients and individual MicroPnP devices. Using these libraries, IoT end-users are offered an easy, but powerful way to rapidly build applications.

Awards & Commercial Applications

MicroPnP was awarded third place in the IPSO Challenge 2015, which evaluated IoT applications and prototypes on their innovation, breadth of applicability, marketability, and ease of use. The ten semi-finalists presented their prototype for an industrial jury at the Designers of Things conference in Silicon Valley in December 2015.

Beyond the IPSO Challenge, MicroPnP is being deployed in various sensing scenarios worldwide that range from home energy profiling to data center optimization (Figure 3), industrial facilities (Figure 4), or even farms (Figure 5). For example, in a data center context, Plug-and-Play sensors, such as temperature, humidity, and AC power monitoring sensors, provide a detailed understanding of energy flows in the environment along with monitoring of appliance power consumption, while Plug-and-Play actuators allow for automatic control of appliances.

Next to energy management scenarios, MicroPnP devices are used to monitor machinery and associated factory infrastructure (Figure 4), providing detection and real-time alerts for leaks or irregular machine behavior. In this situation, the MicroPnP mesh network provides an extremely reliable and extensible communications medium that can extend to cover huge industrial facilities, while operating for up to a decade on a single pair of batteries.

Finally, MicroPnP provides intelligence for precision livestock farming (Figure 5). Farm efficiency is enhanced through Plug-and-Play sensors and actuators that install in minutes to provide live, high-resolution data on animal conditions including: feed consumption, water use, temperature, humidity, air quality and pollution.

Summary

Applications for the Industrial Internet of Things are expected to be deployed in dynamic scenarios and operate reliably for long periods over time. However, most users struggle with the inherent complexities and costs of existing IoT sensing solutions. The MicroPnP platform based on Linear Technology’s SmartMesh IP embedded wireless mesh networking presented in this article adopts a radically different approach to existing solutions and combines a decade of academic research with leading industry wireless networking technology to realize zero-configuration.

To drastically reduce the total cost of ownership for industrial sensing and control systems, MicroPnP offers zero-configuration plug-and-play sensing and actuation peripherals that can be managed from the cloud and that easily integrate with traditional systems. In addition, provides managers with a real-time overview of network operation and device status. Our best-in-class energy management and networking results in a 10-year battery life while retaining over 99.999% network reliability and strong end-to-end security as demanded by the industry.

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News