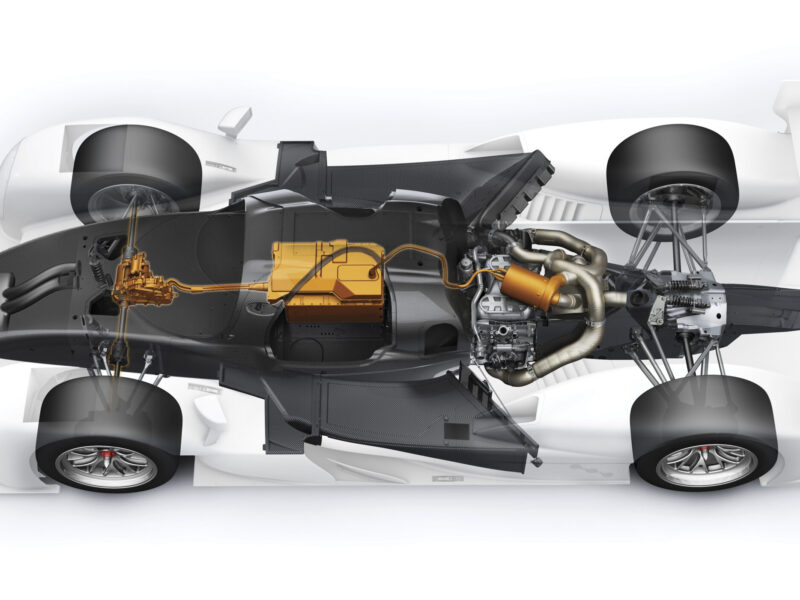

A glimpse to the hybrid powertrain of Porsche’s 919 racing car

With the 919 Hybrid, Porsche has opened new technologies for race vehicles. The two-litre four cylinder turbo engine (Porsche claims that this is the most efficient internal combustion engine the company ever built), utilizes two different energy recuperation systems. During braking, it converts kinetic into electric energy in the front axle. In addition there is a split exhaust system that accommodates the turbo charger – and a second turbine that converts surplus energy into electric energy. This turbine features high energy efficiency at low weight. The converted kinetic energy from the front axle accounts for 60% of the total electric energy gained through recuperation, the energy extracted from the exhaust system to 40%.

The electric energy from these two processes is stored in a lithium-ion battery and used to drive an electric motor if desired. The driver can activate this energy and turn it into additional thrust at any time through the push of a button. The electric motor offers not much less power than the combustion engine: 294 kW electric power add to 368 kW of conventional power. The electric motor drives the front axle while the combustion engine drives the rear axle.

The use and interplay of these two different energy sources requires a rather sophisticated strategy. In each braking phase, the battery collects electric energy. During the Grand Prix circuit on the Nürburgring race track which has a length of 5.148 km (3.2 miles) this is the case ahead of every curve, a total of 17 times. The tighter the curve the more intensive is the braking. Once he passed the apex of the curve, the driver typically wants to activate the stored energy immediately. He does so by pushing the “boost” button.

On long straights, when the vehicle drives along at the highest speed possible, it again recuperates energy, because during such high-speed phases the turbine in the exhaust pipe is generating a maximum of electric energy. The regulations however provide a limit to the amounts of energy both of the combustion engine and the generator: The vehicle must not burn more than 1.8 litres of fuel per lap and not more than 1.3 kilowatt-hours (or 4.68 megajoules) of electric energy. Thus, the driver has to find the best driving strategy and operation point: He needs to stop boosting and take the foot off the acceleration pedal exactly at the right time.

Converted to the 13.629 kilometer lap of the Le Mans race track, which is the scale model for the regulations, the amount of electric energy allowed is 2.22 kilowatt-hours. This equals 8 megajoules, which is the highest energy class stipulated in the regulations. Porsche was the first and in 2015 the only manufacturer that dared to push the limits so far. In 2016 Toyota is also competing in the eight megajoule class. Audi uses six megajoules. The WEC regulations almost completely balance these differences.

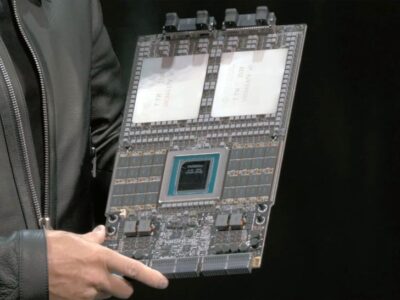

A closely watched and much-discussed decisions regarding the energetic concept and architecture of the 919 Hybrid was the voltage level for the powertrain. This decision influences all other design aspects from battery to control electronics, electric motor and charging technology. Porsche opted for 800 volts, though it was difficult to find components like flywheel generators and supercaps that were designed for this voltage level. The sports car manufacturer selected a liquid-cooled lithium-ion battery made up of hundreds of individual cells, each one encapsulated in a cylindrical metal container. They also had to find the best balance between energy density and power density. Energy density correlates with storage capacity which in turn translates into driving range. Though the requirements for race cars and road cars differ, the 919 acts as a test lab for future hybrid drives from Porsche. The company gained valuable insights for the Mission E which also will have an 800V electric system. By the end of the decade, the Mission E with many components now tested and evaluated in the 919 will be available as a series vehicle.

Read also:

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News