Debonding LED die to tackle supply issues

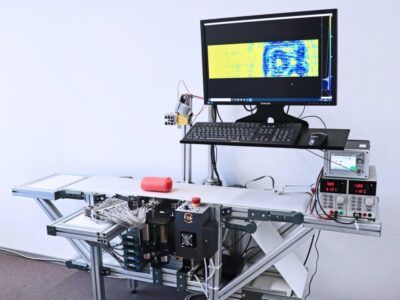

Tresky Automation in Germany has developed a technique for safely and reliably debonding LED die, allowing devices to be reused or replaced.

In times of limited availability of components and materials, reworking takes on a very special significance. This also applies to LED manufacturing, where irregularities in processed LEDs are immediately visible at first sight.

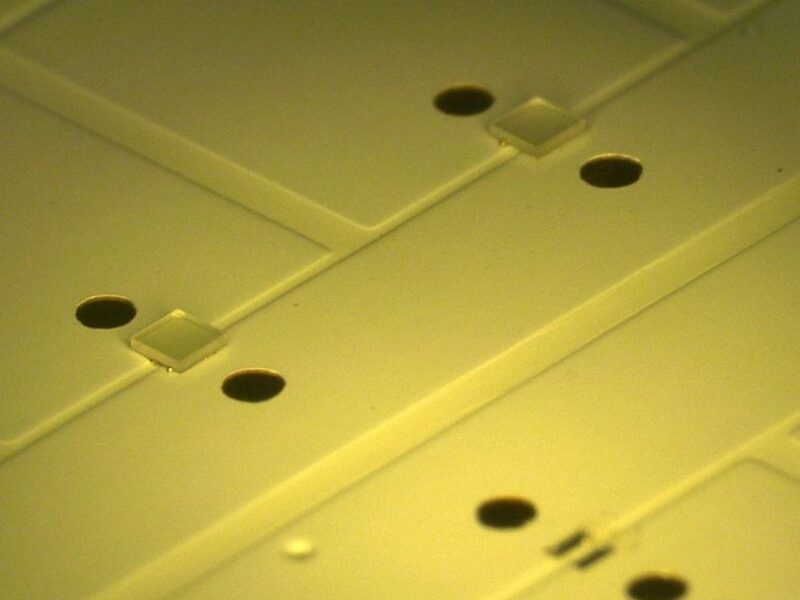

Reworking faulty or incorrectly placed components is one of the more demanding tasks in electronics production. If the components are particularly small or fragile, this work is even more complex. If LEDs are used, a perfect light pattern is usually a prerequisite. For reasons of extremely important quality assurance, it may be necessary to rework LED dies.

“Defective LED dies are a real challenge. These sensitive, easily fragile and very small components are usually processed in tight packing densities and can only be removed and reworked with a lot of knowledge, experience, a lot of tact and the right tools. With the right technology, however, this is possible,” said Daniel Schultze, Managing Director of Tresky Automation.

For this purpose, Schultze and his team adapted a process known from component manufacturing at the request of a customer.

“Our die bonding automation system allows LED dies to be easily and successfully removed in the rework configuration without damaging adjacent LED dies or affecting the solder and its surroundings,” said Schultz.

The debonding process uses a modified scrubbing function, where the adhesion between the LED die and the solder is broken with the help of the heating temperature.

“Once the LED die is separated from the solder, it is carefully picked up by a pick-up tool,” said Schultze. A new die can then be inserted in the same Tresky Automation machine.

As the die bonding systems are designed for high-precision processes, the entire reworking process of the LED dies is carried out according to the specifications of the semiconductor production and is therefore not only exact, but also controlled and reproducible.

Other articles on eeNews Europe

- IR transparent solderable resin for co-packaged optics

- First 5G RAN baseband platform IP for custom chips

- Smart materials for power in Industry 4.0

- Codasip joins OpenHW to push RISC-V verification

- Perforce drives into the semiconductor industry

- Tek, Anritsu team for automated PCIe 6.0 test

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News