Efficient wheel-hub drive platform increases driving range

According to DeepDrive sources and press reports, the patented wheel hub drive is said to develop a torque of over 1,800 Nm and more than 150 kW of power – with an efficiency of over 96 percent. The range of the vehicles can thus be increased by up to 20%, the company advertises.

The engine has been dimensioned to fit a standard 18-inch rim. For this purpose, the company has developed what it calls “a new type of engine technology”. It is characterised by the economical use of resources, production processes suitable for series production and excellent acoustic properties, DeepDrive claims.

The DeepDrive engineers want to solve the often criticised problem of high unsprung masses in two ways. The motor should weigh less than 30 kilograms. If, in addition, two of these motors are mounted on the rear axle of an electric car, it is possible to dispense with a mechanical brake there and thus further reduce the weight of the overall wheel. “The increase in unsprung mass is minimised in this way,” explained DeepDrive co-founder Stefan Ender. The wheel hub motors are designed in such a way that they develop sufficient braking torque even without a mechanical brake.

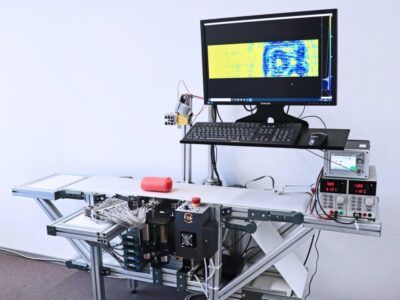

To prove the targeted performance data, the start-up had a prototype scaled in diameter tested at the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research (IFAM) in Bremen. These tests confirmed the efficiency and performance of the developed technology, according to DeepDrive. “The drive was tested with high-quality measurement technology and achieved the predicted efficiency in the started operating range,” confirms Dennis Koch, who is responsible for the design and operation of the motor test benches at IFAM.

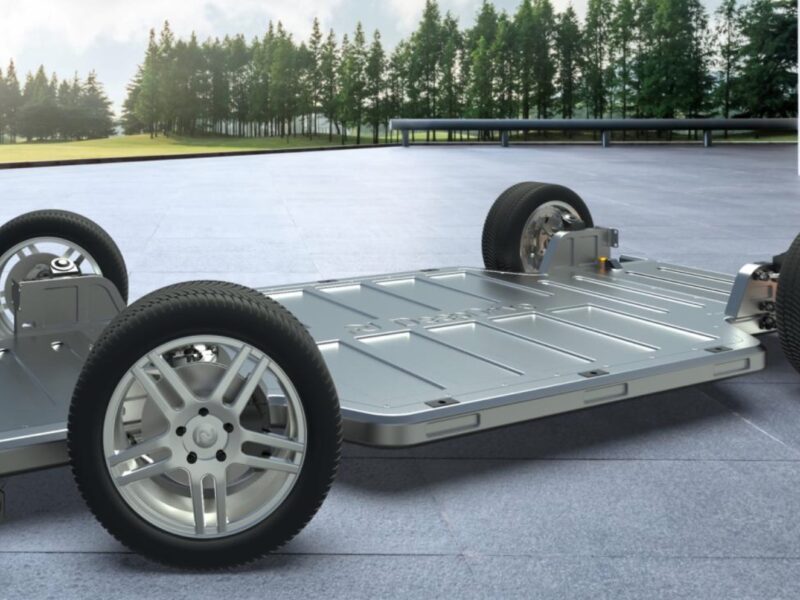

If possible, DeepDrive does not want to supply its own wheel hub motors to a vehicle manufacturer. The company’s goal, on the other hand, is to supply manufacturers with a complete platform with these drives, which is designed for the aforementioned use of the wheel hub motors on the rear axle. “The wheel hub drive forms the technological basis for the flat and modular electric vehicle platform we have developed,” Ender continues. “We don’t want to become a pure supplier of electric drives, but rather enable our customers to fully utilise the advantages of the drive with our platform.”

The DeepDrive platform is a so-called skateboard platform. This means that the traction batteries are integrated into a flat frame; the suspensions and other mechanical elements such as the crash structures are also mounted on this frame. The platform is supposed to be scalable; on its website, the company lists three different sizes – from a decidedly short to a very long wheelbase. However, since the engines are not located in the actual vehicle but in the wheel housing, this results in more space in the vehicle.

According to DeepDrive, the installation space savings achieved with the platform and the efficiency of the overall system thus achieved should make it possible to achieve ranges of over 600 kilometres “even with low-cost battery technologies”. LFP cells and sodium-ion batteries are cited as examples of battery technologies.

DeepDrive plans to present its wheel hub motors at the IAA Mobility in September.

Related articles:

Hydrogen-driven double-decker bus has electric drive axle from ZF

Toyota takes pole position in fuel cell cars

Electric cars: dyes indicate motor wear

Centrally controlled robot vehicles to ensure urban mobility

World’s highest power density through 3D printing

Reimagining the electric vehicle with flat platforms

Vehicle uses torque vectoring for extreme versatile steering

REE Automotive, Magna in strategic deal

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News