Fractus Antennas rebrands as Ignion to focus on the IoT

Virtual antenna pioneer Fractus Antennas is no longer about fractal antennas. The company, set up in 2015 as an independent product company for technology developer Fractus, has changed its name to Ignion and is to focus on the Internet of Things (IoT).

“The reason why we did the name change is we are in the second wave,” said Jaap Groot, CEO of Ignion in Barcelona. The city is about to host Mobile World Congress, and the change in name from Fractus Antennas to Ignion reflects the changes in the mobile industry, he says.

The company was originally launched around technology from the local Catalonian Polytechnic University (UPC) and licensed to a startup vcalled Fractus, co-founded by Ruben Bonet and Dr Carles Puente, who is also VP of Innovation a co-founder of Ignion. As a pioneer in developing internal antennas for smartphones, tablets and other wireless devices, Fractus has over 120 patents and patent applications in the United States, Europe and Asia and has won a number of court cases against companies such as ZTE.

““The first wave was mobile phones, where the Fractus technology is designed into 99 percent of all mobile phones,” said Groot at Ignion. “They signed up all the major players and there are billions of fractal designs.”

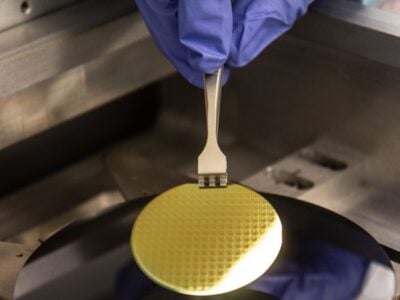

“We can do the same for the IoT,” he said. “IoT is struggling not just because of proof of concepts and fragmentation but it is difficult to do it right,” he said. To help with this, Fractus Antennas developed an ‘antenna booster on a chip’ technology called Virtual Antenna that cuts the development time for IoT antenna designs from months to weeks. This supports multiple cellular and non-cellular technologies, ranging from NB-IoT and LTE-M to low power LPWAN and Bluetooth by using the board as the antenna.

Next: Virtual antenna

In 2015 the company developed a surface-mounted non-resonant antenna booster that can be tuned to any frequency. There are now eight products from 600MHz to 10.6GHz, and as Ignion the company has 1500 OEM and ODM customers and already supplies 25m chip antennas for IOT says Groot, who joined the company last year from LoRa wireless chip maker Semtech and has been the Vice Chair IoT for the Wireless Broadband Alliance (WBA) and vice chair of Europe for the LoRa Alliance and worked Qualcomm, MiX Telematics and Sigfox.

“The basic concept came from the PCB as the biggest piece of metal in a device and it uses the groundplane that we can tune through a matching network, eg a board size match to ignion network calculated – every customer gets a custom antenna but the booster is a standard component,” said Groot. “The new product line is doing the same for IoT,” he said. “This is a standard off the shelf product that can be used in the majority of the IoT use cases, battery, multiband, multiradio.”

“Typically the lower the frequency the bigger the PCB, the boost remains the same size so we use the PCB ground plane, for example we increase the board size to boost the efficiency or use an external antenna.”

The company is not addressing the 433MHz band that is opening up for IoT applications. “We have designs but you end up with a board that measures 120 x 60 cm. We also have less differentiation at 28GHz in the mmwave band as the higher the frequency the products get very small. Instead we focus on multi radio and multi band with one product with three I/O with GNSS and cellular in one antenna.”

The company uses a three stage integration process with a tool that places the antenna booster on the PCB virtually. Ignion then designs the first matching electronic circuit for the required frequency bands, all of which is optimized for the device’s designated board within 24 hours. This allows device radiation performance to be predicted from the very beginning.

Addressing the numerous applications across the IoT market will take more resources. “We are a relatively small company with 35 people so we have to focus,” said Groot. “What we do today is we have completely automated the design internally. This has gone from 5 hours to 5 minutes.”

The company also make use of the thousands of designs it has already done to simplify the process for new designs. This allows the team to focus on design challenges it hasn’t met before as multiple antennas are used in IoT designs.

“Over the last 9 months we have added one or two new people and we are scaling up. It is not so much in the engineering which is the biggest department and they need to automate and use their expertise on MIMO and 8 x 8 antennas but our main goal is to be involved in the higher level of the designs that can reach higher volume, for million piece contracts.

The areas that are doing well is smart metering and we are in with the biggest guys, tracking devices, that’s very hot. “Over 2.7bn devices will be built and shipped this year in the IoT so I can easily grow this business by making sure the engineers enjoy working with us and get faster and better results,” he said.

Roadmap

He is also looking at the role of the antenna in energy harvesting systems to capture RF energy to boost the battery life in IoT designs. “What we are looking at is how to capture the energy that is available and put it back into a supercapacitor or rechargeable battery at the edge. “We can do this now, and now its down to finding the right partnerships to apply the technology,” he said.

The company already works with energy harvesting power management chip designer e-peas in Belgium on ways to increase the range and power budget of IoT boards. “It’s now a matter of making it a product line,” he said.

Related articles

- Module-antenna combo simplifies IoT development

- Dual-band GNSS/BT embedded antenna for IoT

- Virtual Antenna for easy design of embedded IoT antennas

- SMT multiband antenna for mobile and wireless devices

Other articles on eeNews Europe

- Micron, Mouser sued in Germany

- Intel to offer RISC-V core in 7nm foundry

- Chip shortage hits payment cards

- Presto in exclusive Cadence deal

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News