Kyocera teams for energy harvesting sensor buoy

The design of the smart buoy combines Nagasaki University’s tidal current power generation technology with Kyocera’s IoT technology to collect reliable ocean data. Prototype buoys can collect a wide range of data on the marine environment using self-generated energy.

A pilot program gathered information from 21 sensors, monitoring everything from water temperature and humidity to current direction. Future development may include sensors for temperature-related salinity variation, chlorophyll turbidity, and temperature-related variations in dissolved oxygen concentrations without needing recharging.

Maintaining a stable power supply is a big challenge for continuous data collection at sea. The smart buoy design generates its own electric power for continuous ocean data collection using a tidal-current power generation system in the buoy. Kyocera has plans to extend the technology to monitor fisheries and aquaculture, conduct ocean surveys, and more.

The smart buoy uses the tidal-current power generation system to supply power to the Kyocera GPS multi-unit and connected sensors. The GPS multi-unit is a compact Kyocera IoT device with an RS-485 interface to link to sensors and antennas and is compatible with GPS, GLONASS, and Michibiki location tracking systems, powered by a 54Ah secondary battery that is recharged by the tidal generators. The wireless link back to land is via an LTE Cat M module.

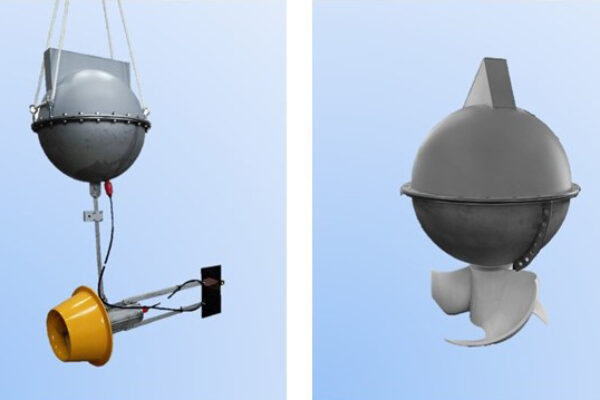

Each prototype is equipped with two different tidal-current power generation systems. In the SLTT (Small Lens-type Tidal Turbines) the 1800mm high buoy and power generation are separate, and a diffuser is installed around the turbine. In addition to protecting the turbine, the diffuser has the effect of increasing the flow of water for better power generation.

In the VTT (Vertical-axis Tidal Turbine) 910mm high version the power generation element is directly connected to the buoy. Its AI-guided design incorporates a tilted axis to optimize turbine rotation amid heavy ocean swells and waves.

The next step for the project is developing commercial versions that are smaller and lighter and can carry an underwater cameras as well as a water temperature-salinity sensor (temperature, salinity, and electrical conductivity), chlorophyll turbidity sensor (chlorophyll, turbidity, and water temperature) and DO sensor (dissolved oxygen and water temperature)

Kyocera will also build an IoT platform to store collected data, and ongoing testing will be conducted mainly in Nagasaki Prefecture.

Related articles

- R3-IOT raises $4.3m for fish farm satellite connections

- German researchers show kinetic energy harvesting systems

- Smallest energy harvesting chip for wearables and IoT

- Flexible antenna captures 5G power for IoT

- Dutch energy harvesting PMIC boosts NB-IoT chip

Other articles on eeNews Power

- Silanna plans own USB-PD controller, wall socket design

- First electric car charging cable with integrated technology

- World’s smallest supercapacitor powers medical sensor

- European tech for immersive cooling

- Continuous dry coating process for battery electrodes cuts costs

- Analog Devices teams with German battery digital twin startup

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News