PCBs a ticking timebomb says Dirk Stans at Eurocircuits

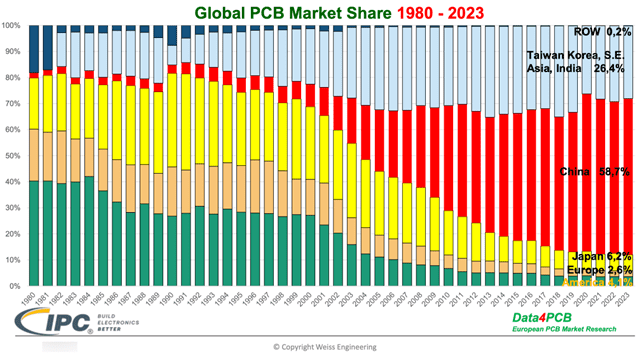

PCBs are the foundation of every electronic device. No chip works without one. Yet Europe, with its ambition to lead in semiconductors and high-tech, produces less than 3% of the world’s PCBs. This is a critical vulnerability in the industrial strategy, Dirk Stans tells eeNews Europe for its Leaders’ Talk series.

Stans is managing partner of PCB maker Eurocircuits and chair of FHI, the Dutch federation of technology, representing over 600 member companies. “At Eurocircuits, we see every day how thousands of European designers depend on fast, reliable, local production to turn ideas into prototypes and small series,” he says.

“European PCB manufacturing is not a nice-to-have. It is an industrial necessity if we want to control our innovation cycles, safeguard jobs, and remain competitive in high-value sectors. Europe’s electronics future is not something we can buy from others. It’s something we must build ourselves, with our people, our values, and our industrial backbone.”

Is there a practical opportunity for bringing volume production back to Europe? Is this necessary as a sovereign capability?

Bringing back all volume production is unrealistic, but selective reshoring is both practical and necessary. We need sovereign capability in key strategic sectors:

- Defence

- Medical technology

- Critical infrastructure

- High-reliability industrial systems

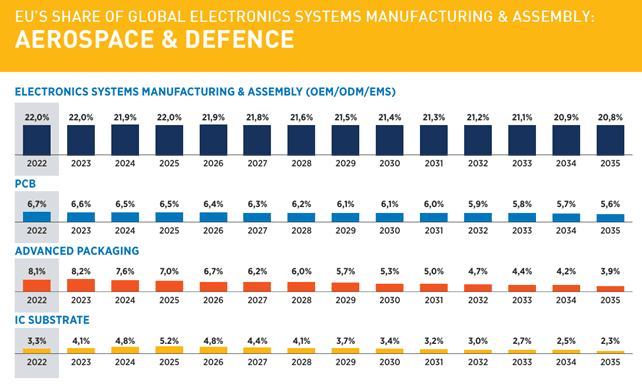

This is an example what would be needed for Aerospace & Defence:

Volume alone is not the answer. Digital-first manufacturing, flexible small-to-medium series, and design-to-production integration must lead the way.

By connecting Europe’s engineering talent with Europe’s manufacturing strength, as Eurocircuits does with its online platform serving over 11,000 European companies, we create an ecosystem that is fast, responsive, and resilient. That is far more valuable than cheap mass production alone.

Why does this matter?

Europe cannot afford to outsource control of its future. Whoever makes your building blocks, owns your destiny. Electronics is no longer just for consumer gadgets; it powers everything from healthcare and energy grids to military systems and transportation. If we lose the capability to make what we invent, we risk becoming dependent on other continents, whose interests may not align with ours.

Bringing back manufacturing know-how strengthens our economy, our security, and our strategic autonomy. It also builds better jobs and protects European values like fair wages, environmental responsibility, and ethical production, something we at Eurocircuits are deeply committed to.

What is the risk of using foreign suppliers?

Price is never just price. Some Asian suppliers sell PCBs below material cost, not to win business, but to harvest data. Your designs. Your IP. Your future market position. We now have independent studies confirming that layout data alone reveals valuable industrial intelligence.

And let’s be honest, if your cheapest supplier disappears, or if geopolitics closes the trade routes, what is your backup?

Europe has been sleepwalking into dependency. It’s time to wake up, secure our supply chains, and invest in trusted, local manufacturing partners. The clock is ticking, and that is what frustrates me the most.

Does the move to high density interconnect (HDI) and more automation allow manufacturing to return to Europe?

At Eurocircuits, we’ve proven that automation, smart tooling, and HDI pooling make it possible to produce complex, high-density boards right here in Europe, competitively, quickly, and at scale. We help engineers get it right first time with online design feedback, DRC/DFM integration, and data-driven production.

This digital-first approach turns Europe’s engineering creativity into manufacturing reality, closing the loop between idea and industrialisation. It’s not science fiction. We do it every day, for prototypes and small series that fuel Europe’s innovation.

Do we have the skills in Europe for this? How can companies boost skills without free tools and keep IP safe?

Yes, we do. But we need to protect and grow those skills. At Eurocircuits, we support thousands of students and start-ups through our Academy initiatives. We help them learn the right manufacturing practices from day one.

But tools alone are not enough. Trust matters. Who owns your data? Who sees your IP? We believe in European platforms, hosted in Europe, where your data stays yours. Let’s build open knowledge, not open IP. That’s how Europe stays strong and safe.

What is your view on tariffs for imports into Europe? Will this just lead to production in other countries than China? And how do you think China will respond to that?

Tariffs alone won’t save Europe’s industry. They delay the pain, they don’t solve it.

We need smarter procurement policies, like EU-origin-first rules when taxpayers’ money is spent.

If public money stays in Europe, private investment will follow.

China may move production to other countries to bypass tariffs, but they can’t easily bypass European trust.

If we make quality, reliability, and ethical production our competitive advantage, Europe can win without hiding behind tariffs.

How many times in the last 12 months were you were truly upset. And about what?

Too many to count, but one thing keeps me awake: After two years of raising awareness in industry and politics, I still see too little action. I see brilliant engineers and trusted manufacturers ready to build Europe’s future, but policies that reward the cheapest offer, regardless of origin.

I see calls for European sovereignty, but no practical tools to secure our raw materials or data. We don’t need another study. We need practical, scalable action. The clock is ticking, and that is what frustrates me the most.

- Retain Public Funds within the EU Economy

- Creation of an EU Electronics Raw Materials Database

- Standardising standards to support EU industry competitiveness

Why are industry associations often so predictable and almost never act like angry or clever activists?

Because most associations fear losing their seat at the table. They try to be diplomatic and balanced, but sometimes anger and urgency are exactly what’s needed.

At Eurocircuits, I prefer action over position papers. That’s why I publish open letters, challenge policymakers, and call on my fellow industrialists to speak up.

We can be polite and passionate at the same time. Europe needs clever activism, not just another polite debate.

Europe’s electronics future is not something we can buy from others. It’s something we must build ourselves, with our people, our values, and our industrial backbone.

At Eurocircuits, we prove every day that European manufacturing is alive and kicking. But we need more allies. Not more talk, but more action.

Not more excuses, but more ownership. Let’s build the Europe we believe in, one PCB, one partnership, one future at a time. Let’s make it right first time, right here in Europe.

- IPC call to action

- Report details what must be done to ensure the long-term relevance of PCB industry

Dirk Stans is Managing Partner at Eurocircuits, a European leader in PCB and assembly manufacturing for prototypes and small series. With over 30 years of hands-on industry experience, Dirk is a passionate advocate for strengthening Europe’s technology manufacturing base.

He actively engages with policymakers, industry associations, and the engineering community to promote sustainable, digital-first production in Europe. Dirk is known for his direct, practical communication style and his leadership in bridging the gap between design and manufacturing.

In addition to his leadership at Eurocircuits, Dirk serves as Chairman of FHI, the Dutch federation of technology branches, representing over 600 member companies. With more than 20 years of active engagement, Dirk has been instrumental in promoting industry collaboration, reducing regulatory barriers, and securing a strong voice for SMEs in both national and European policy discussions.

Through Eurocircuits’ online platform, Dirk and his team help over 11,000 European electronics companies bring their ideas to life right first time.

Do you have a strong opinion about an electronics-related topic? If you have a strong take about a key topic in the industry, we want to hear from you.

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News