Printed electronics opens up large flexible sensor design opportunities

Compared to traditional electronic solutions, printed electronics offers several differentiating factors which make them particularly well suited to sensing application. Most printing processes are compatible with large area substrates, which enable the design of large area sensors with sensing capabilities across surfaces of up to 500x500mm. This at a very competitive cost per area ratio (compared to amorphous silicon or CMOS technologies).

A pioneer in printed electronics applied to optical sensors, Isorg addresses several markets and functionalities. This includes scanning surfaces for X-ray

digital imaging with the co-integration of organic photodiodes with transistors on amorphous silicon, photodiodes combined with organic transistors on

plastic substrate.

In the future, substituting amorphous silicon technology with organic electronics will increase cost competitiveness and enable new products developments

(for lighter and more robust portable equipment).

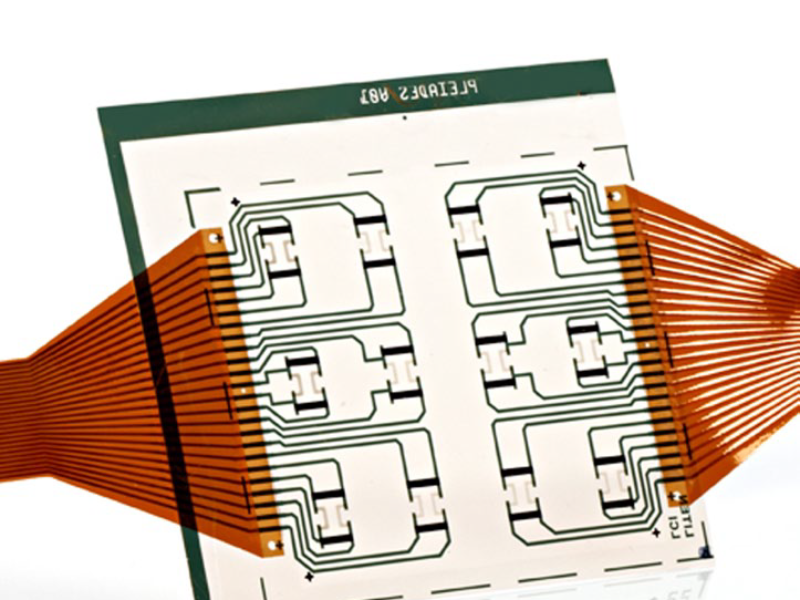

The first demonstrator of such a full organic image sensor is being fabricated as a collaborative development between Isorg and Plastic Logic. More particularly, the collaboration focuses on the deposition of organic printed photodetectors onto a plastic organic thin-film transistor backplane, to create a flexible sensor with a 40x40mm active area, 375um pitch (175um pixel size with 200um spacing) and a 94×95 = 8 930 pixel resolution – see Figure 1.

Fig. 1: Plastic image sensor prototype (Isorg / Plastic Logic)

Biometrics applications using fingerprint and palm recognition could use printed electronics to substitute the typical CMOS-based sensors with thinner and lighter organic solutions. Current developments yield a pixel resolution of 50um. Such approaches could also enable the design of large scanning surfaces to substitute CCD line scanners in office equipment, yielding faster, lighter and thinner document scanners. So far in this field, a pixel resolution of 80um has been achieved for a 300 dpi document scanning resolution.

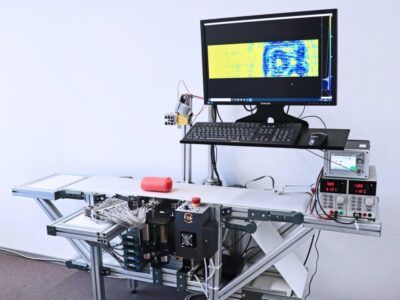

Printed electronics also finds its way in temperature sensors in printed electronics (Figure 2), applying its large area sensing capabilities to the detection of hot spots, for example to monitor the power distribution and heat dissipation in power electronics

circuit boards.

Fig. 2: Printed temperature sensor (Isorg)

Thin and flexible: a system-on-foil approach

Using PET as a substrate, it is now possible to design systemon-foil sensing solutions that combine optical sensors, discrete components such LED and flexible interconnections. In this way, contactless user interfaces can be built using organic

photodetectors, offering functionalities such as hand proximity detection and gesture recognition for power on/off or linear control (slider and vertical distance detection).

These conformable system-on-foil user interfaces can even be integrated in smart

textiles products. The optical solution relies on the detection by organic photodetectors of the reflected infra-red light emitted by IR-LEDs directly mounted on a flex circuit, as shown in Figure 3. For this purpose, the organic semiconductor materials can

be tuned to operate both in visible and near infra-red bands.

Being very thin and easy to glue to other substrates such as paper, these new sensors can easily turn plastic and paper into interactive surfaces for merchandising and smart packaging solutions or to detect nearby motion. Another use case for such optical sensors is to integrate NIR emitting LEDs and organic photodiodes at the periphery of a surface so that any object left on the surface can be spotted through the detection of light path occlusion – see Figure 4. Such applications are under development for industrial products and multi-touch user interfaces and displays.

Fig. 3: Flexible proximity detection and gesture detection by

organic photodiodes (Isorg)

Retrofit sensors

Because flexible and printed electronics foil sensors are easy to glue, they can easily be fitted to existing equipment. For example, Isorg is investigating the use of optical sensors for spatial spectroscopy as an in-line process control for the pharmaceutical

industry. These sensors could be stuck to the windows of existing equipment. The same would apply for temperature sensor arrays used in power distribution appliances (by gluing the sensing plastic foil directly on the equipment door). Object detection sensors could find their way in logistics.

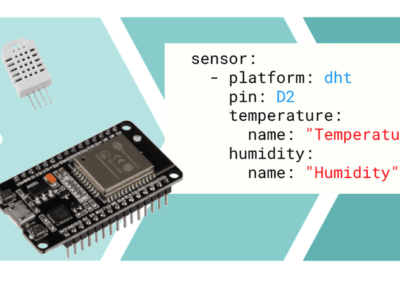

All these new developments require the cooperation of new players from the printed electronics and conventional electronics industries. System-on-foil approaches call for new substrates (PET, PEN), new attach materials (low temperature conductive glue), new conductive materials (printable copper and silver inks, TCO Transparent Conductive Organic materials) as well as new assembly and inspection equipment (pick-and-place machines, visual inspection, oven).

Laurent Jamet is co-founder and business development director of ISORG – www.isorg.fr – he can be reached at laurent.jamet@isorg.fr

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News