Vitesco rolls new generation of electric axle drive

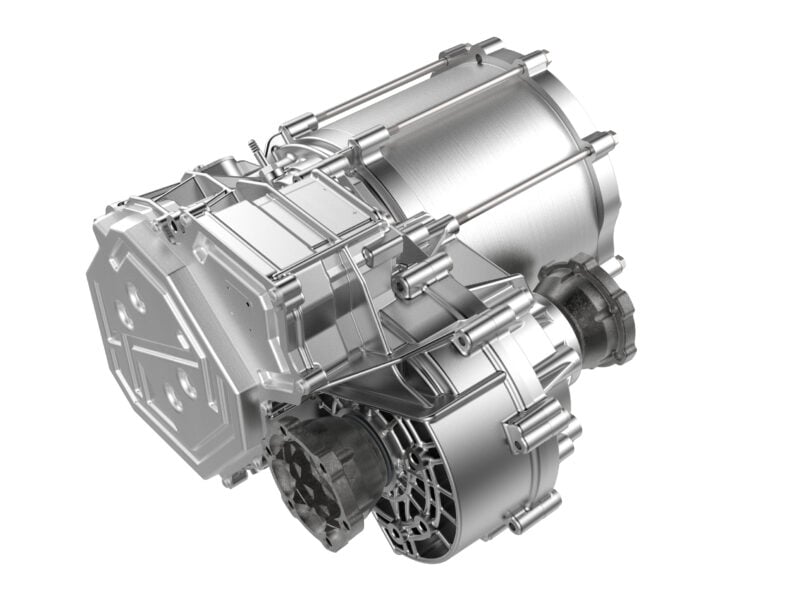

The Vitesco drive platform is designed for power requirements from 80 kW up to 230 kW. Thanks to development and industrialisation experience with predecessor models such as the EMR3, the new platform has a rather high level of integration. it is modularised, scalable and standardised. This allows vehicle manufacturers worldwide to offer different performance levels of the drive in one model without having to touch interfaces or mounting points. Compared to the EMR 3, which is used in successful vehicles such as the Opel Corsa-e, the EMR4 is more energy efficient. It weighs 25 percent less with the same performance and is cost-optimised at the same time.

The automotive industry is currently facing the major challenge of electrifying numerous other vehicle brands and segments. “The market is emphatically demanding the greatest possible scalability and maximum efficiency. The EMR4 platform fulfils exactly these requirements,” said Gunter Mühlberg, Head of Product Management Axle Drives at Vitesco Technologies. It is already the fourth generation of highly integrated “Electronics Motor Reducer (EMR)” from Vitesco Technologies. The EMR4 surpasses the current third generation in weight and size reduction as well as higher power density. The new generation delivers up to 5 per cent more final drive efficiency, much greater scalability between 80 kW and 230 kW, and significant cost advantages.

The drive was presented at the 13th Transmission Symposium China in Shanghai. “China is one of the most dynamic countries in terms of electrification. That is why we decided to introduce the EMR4 platform here, during the prestigious Transmission Symposium China,” said Changsong Yu, Head of the Electrification Technology Business Unit in Asia. “The EMR4 will be manufactured in China, among other countries, based on a local network of supplier partner companies.” All variants of the EMR4 platform can be manufactured on just one production line. Production in Tianjin, China, will supply both local and international car manufacturers with the new powertrain.

Related articles:

Vitesco builds drivetrain controller for Volkswagen’s MEB platform

Vitesco picks Rohm for efficient e-drive technologies

Vitesco establishes R&D center in China

Vitesco supplies e-drive for PSA and Hyundai large series models

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News