60-GHz link breaks record as Industry 4.0 cable replacement

Researchers from Universitat Oberta de Catalunya in Spain have found that 60 GHz mmWave signals can be used in industrial automation as cable replacement, setting up a record 110m link.

The study by Cristina Cano and Prof Xavier Vilajosana at the the Wireless Networks (WiNe) group at the Internet Interdisciplinary Institute (IN3) opens the door to the use of wireless technologies with power and reliability that are comparable to fibre optics and that could replace cables.

The research project has created the first parameterization of a mmWave signal propagation model for gigabit wireless in industrial environments. The researchers say this is the first step towards understanding how this type of signal behaves in an industrial plant and could have a significant impact on the development of Industry 4.0.

“This study is aimed at making communication less expensive and more flexible by incorporating mobile devices into the manufacturing process, something that could be very useful in moving towards Industry 4.0,” said Cano. “This allows, for example, connecting freely movable robotic arms to the production process or establishing communications for data reporting, and controlling or stopping the different components of the process in an emergency. But it could also allow the worker to be a part of the process.”

“The research in this field can be applied to replace cables in the monitoring processes of production lines where very quick and reliable decisions have to be taken,” she said. “For this reason, we must be able to guarantee that when an emergency message is sent to stop the production process, it arrives in the required time and its reception is highly reliable. Otherwise, if the message is lost or arrives late, the consequences could be disastrous.”

There are currently several propagation models of mmWave high-frequency signal, but none in industrial facilities.

The study found that typical surfaces in industrial plants, such as reflective pipes, are very beneficial for mmWave links as they allow the signal to travel along various paths and reception is reinforced, allowing greater coverage. “Specifically, we were able to establish a 110m link, the largest [sic] communication link achieved with the IEEE 802.11ad standard to date,” she said.

“A model is a representation of reality that, using equations, allows us to predict what will happen to the signal in each environment,” she added. “There are several models for millimetre bands in office and urban settings, but there are hardly any in industrial settings. These sorts of facilities differ in many ways which could interfere with the behaviour of the wireless signal, such as the height of the ceiling, the material of the walls and floors, or the type of machinery they contain. Our research has allowed us, for the first time, to establish the parameters for an industrial environment.”

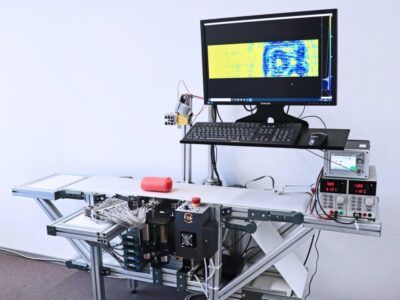

The researchers were able to measure the behaviour of the mmWave signals at the ALBA synchrotron, an electron accelerator in Barcelona, Spain. The facilities have characteristics that resemble different industrial environments in large production plants, such as refrigeration facilities, server rooms and experimental halls.

“It is very difficult for the scientific community to access a manufacturing plant for testing, which is why we believe that this type of model has taken so long to be parameterized,” said Cano. “We have been able to advance in this investigation thanks to the ALBA synchrotron, which allowed us access to its facilities. These facilities are very similar to those that we might find in an industrial setting and, also, since we carried out the tests when the accelerator ring was stopped, we were able to access the interior and experiment with the signal in these bands in such a specific environment. We believe that it has been a unique opportunity.”

This model is the first step towards understanding how this type of signal behaves in this environment, but protocols must be established to guarantee the reliability required for this sort of communication by the manufacturing industry in its critical processes.

The industrial mmWave model is accessible to the entire research community. “The parameters that we provide in the article are useful to predict how the signal will behave in an industrial environment. They can, for example, be configured in a simulator to simulate different configurations and obtain a result that reflects the real situation. In this way, it can help other researchers to design protocols that guarantee the correct functioning of the network,” she said.

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News