750V trench SiC FET takes on silicon

UnitedSic has launched its fourth generation of silicon carbide FET, moving to a 750V trench device that the founders believe will shake up the market.

“We are going to put silicon to bed,” said Chris Dries, CEO and founder of UnitedSiC tells eeNews Europe. “We took the feedback on Gen3 which has been out for three years now and we built an entirely new platform.”

“For new 18mΩ and 60mΩ FETs we’ve added a 750V platform option as the lead devices for our customers that want to operate at 400 and 500V while improving all the key figures of merit. We’ve improved the switching performance and because the device is so much smaller we’ve reduced the output capacitance,” he said. Thecompany has Analog Devices as a strategic investor.

As with previous devices, the new parts use a silicon MOSFET co-packaged with the SiC normally-on JFET. This allows a gate drive of +/-20V with a 5V threshold voltage so that all devices can be driven with 0 to +12V gate voltages. This means they work with existing SiC MOSFET, Si IGBTs and Si MOSFET gate drivers and operate up to 500kHz.

“We are able to maintain a 0 to 12V gate drive with a 5V threshold for good EMI immunity and that gives us ability to directly replace silicon,” said Dries.

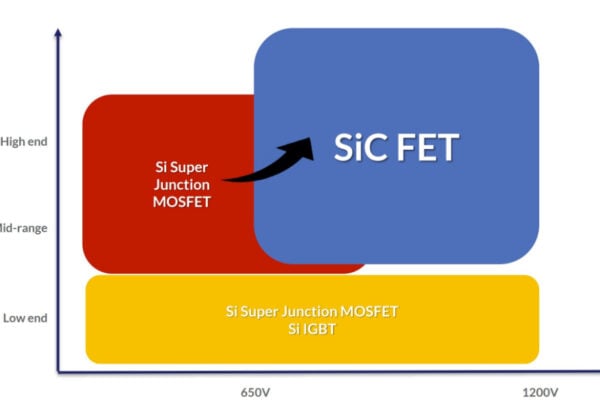

The move to a trench process is key for a smaller die. “Because of the die shrink we can be cost competitive with silicon superjunction,” he said. “That’s a $1bn business that we are compatible with, with SiC performance, for the same price as [silicon] MOSFETs.” Pricing ranges from $3.57 for the 18mO RDS(on) version to $7.20 for the 60mO version.

This also competes with gallium nitride, he says. ““Our die size is a fraction of GaN lateral devices so we will go head to head on price performance against GaN,” he said.

“We did trench in the Gen2 platform then we decided to come out with a planar platform with the 6in 150mm products as it was easier to move rapidly while we brought trench to 150mm, we will support Gen3 for many years to come,” he said.

“You have to have your own technology and we ported that to the foundry, we source substrates from four different supply chains. One of the great things is we run across four supply chains with equivalent yields,” said Dries.

The devices are aimed at on-board chargers and traction designs in automotive, industrial charging, telecom rectifiers, datacentre power factor correction and DC-DC converters as well as renewable energy and energy storage.

Related SiC articles

- DRIVING DOWN THE ON RESISTANCE OF SILICON CARBIDE TRANSISTORS

- FOUR LEAD KELVIN PACKAGE FOR DROP IN DEVICES

- $1BN SILICON CARBIDE BOOST AT CREE

- MICROCHIP STARTS SILICON CARBIDE PRODUCTION

Other articles on eeNews Europe

- AI detects Covid-19 through breath sounds

- Panasonic finally looks at European battery gigafactory

- Slovakia aims to build world’s fastest AI supercomputer

- Dyson to spend £2.75bn on new technologies

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News