Driver chip makes piezoelectric haptics energy efficient

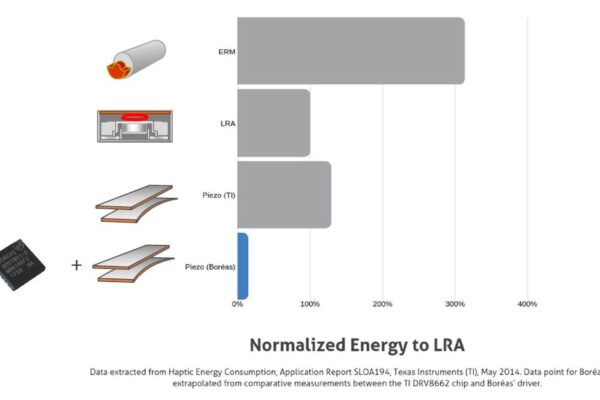

According to the manufacturer, the 4x4x0.8mm chip delivers 10X power savings over its nearest piezoelectric competitor as well as 4X to 20X power savings over other incumbent technologies such as Linear Resonant Actuator (LRA) and Eccentric Rotating Mass (ERM) vibration motors which are much bulkier than piezoelectric haptic solutions.

When interviewed about the new chip by eeNews Europe, Simon Chaput, founder and CEO of Boréas Technologies would not reveal the tricks the driver plays to considerably reduce power consumption, except that it was based on Boreas’ patent pending CapDrive technology platform, a proprietary scalable piezoelectric driver architecture.

Piezoelectric actuators are very promising and very interesting things have been done in the lab, such as creating surface textures or using multiple actuators at the periphery of displays to localize haptic effects on screen through beam forming. But according to the CEO, all these applications have been impractical for volume production due to their high power consumption.

“The piezoelectric actuator itself is very energy efficient, but the electronics for driving it was always very inefficient. Often, you need to drive them at voltages of 50, 100 or even 200V.”

“The BOS1901 is completely different from what has been done in the past. We offer a digital front end that can take from 1.8 to 5V and designers can use any waveform in a digital format. They can use any haptic effects that have been developed before, and we provide a few example waveforms in a development kit” said Chaput.

actuators.

According to the CEO, every low cost haptic solution using a LRA now will want to use a piezo solution for improved user interface, customized user-experience by software with reduced energy requirements.

“It’s a win on all fronts”, said Chaput, noting that even as haptics becomes more and more important in smartphone user interfaces, if you impact battery life when implementing a new feature, it is hard to get in.

Offering a low latency response with a start-up time under 300µs, and with a drive amplitude of 190V peak-to-peak from a 3.6V supply, the chip can drive actuators from DC to 300Hz or even higher to enable realistic haptic feedback effects without draining the battery of mobile products.

The new chip can drive up to two actuators, but it is more of a technology demonstrator for now and the company is engaging with different customers to discuss future product requirements, possibly capable of driving more actuators simultaneously. Another interesting aspect of the driver is that it can take advantage of the piezoelectric element as both an actuator and a sensor. Its built-in circuitry can sense the piezoelectric voltage that an actuator would produce under pressure.

That means that as users press harder on their screen, they could get a different haptic response.

“This feature is a cost cutter” highlighted the CEO. “From a components’ perspective, the piezoelectric actuators are more expensive, but removing sensing electronics can make the overall solution more economical” Chaput explained.

development kit for interactive piezoelectric

haptic feedback.

According to market research firm BCC Research, the global market of haptic actuator and driver ICs will reach US$26.528B by 2022, with US$13.7B of that representing driver ICs. And with its CapDrive technology platform, Boréas aims to displace legacy haptic technologies, notably ERM and LRAs which are limited by higher power consumption, large size, and slower response times.

While most of 2019 will be spent on designing the chip into new products, the CEO expects its first drivers to be in consumer products early 2020.

Boréas Technologies – www.boreas.ca

Related articles:

How to easily add haptics to your display

Thin flexible tactile actuator for wearable haptics

When haptics let you feel the music

Augmented reality gets physical with haptics

Plug-and-play haptic module enables mid-air tactile interactions

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News