French startup promises meaningful haptics

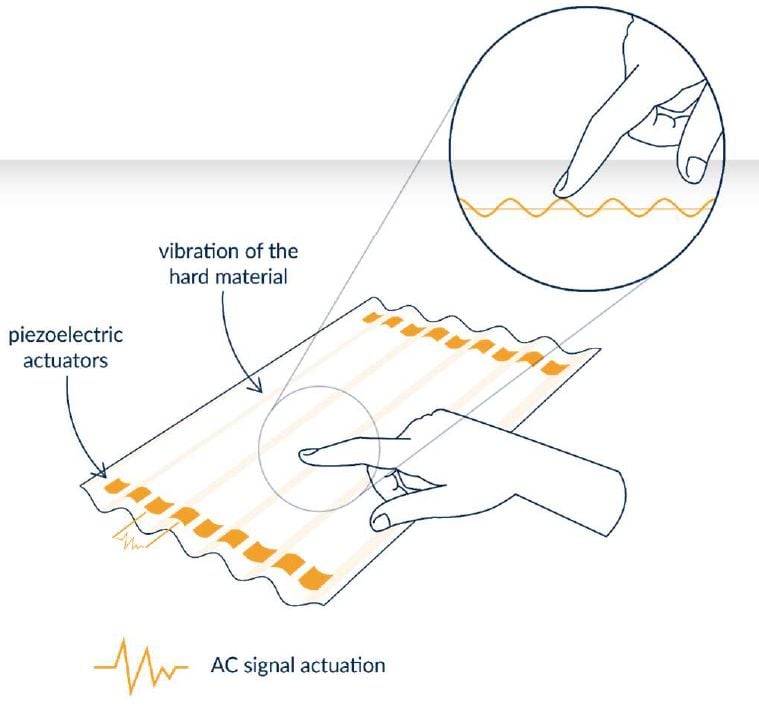

In a demonstrator haptic smartphone display dubbed the Hap2Phone, the company uses a series of thin-film piezoelectric actuators lined up along two parallel edges of the display to modulate the friction coefficient of the glass’ surface by activating precise vibrational modes in the material, creating distinct variations in touch sensations.

of the surface to touch. Driving them with an AC signal

creates an ultrasonic standing wave in the material.

“The friction of flat screens can be globally modulated by the application of ultrasonic vibration with varying amplitude to create the illusion of a texture” reads an academic paper co-authored by the company’s CEO Cédrick Chappaz. “We can describe this as ultrasonic lubrication, the discontinued contact due to the vibrational modes leads to a friction reduction” Chappaz explained eeNews Europe when interviewed about the technology.

of Hap2U’s piezoelectric actuators.

According to the company’s CEO, by modulating the friction coefficient at various touch-points, these haptics can deliver touch sensations ranging from intense to soft clicks, springs, buttons or gliders, even giving a feel for elasticity and all kinds of high-to-low elevation points and textures. It is the changes in friction detected by the nerve endings in the user’s fingertips that are interpreted by the brain as different textures.

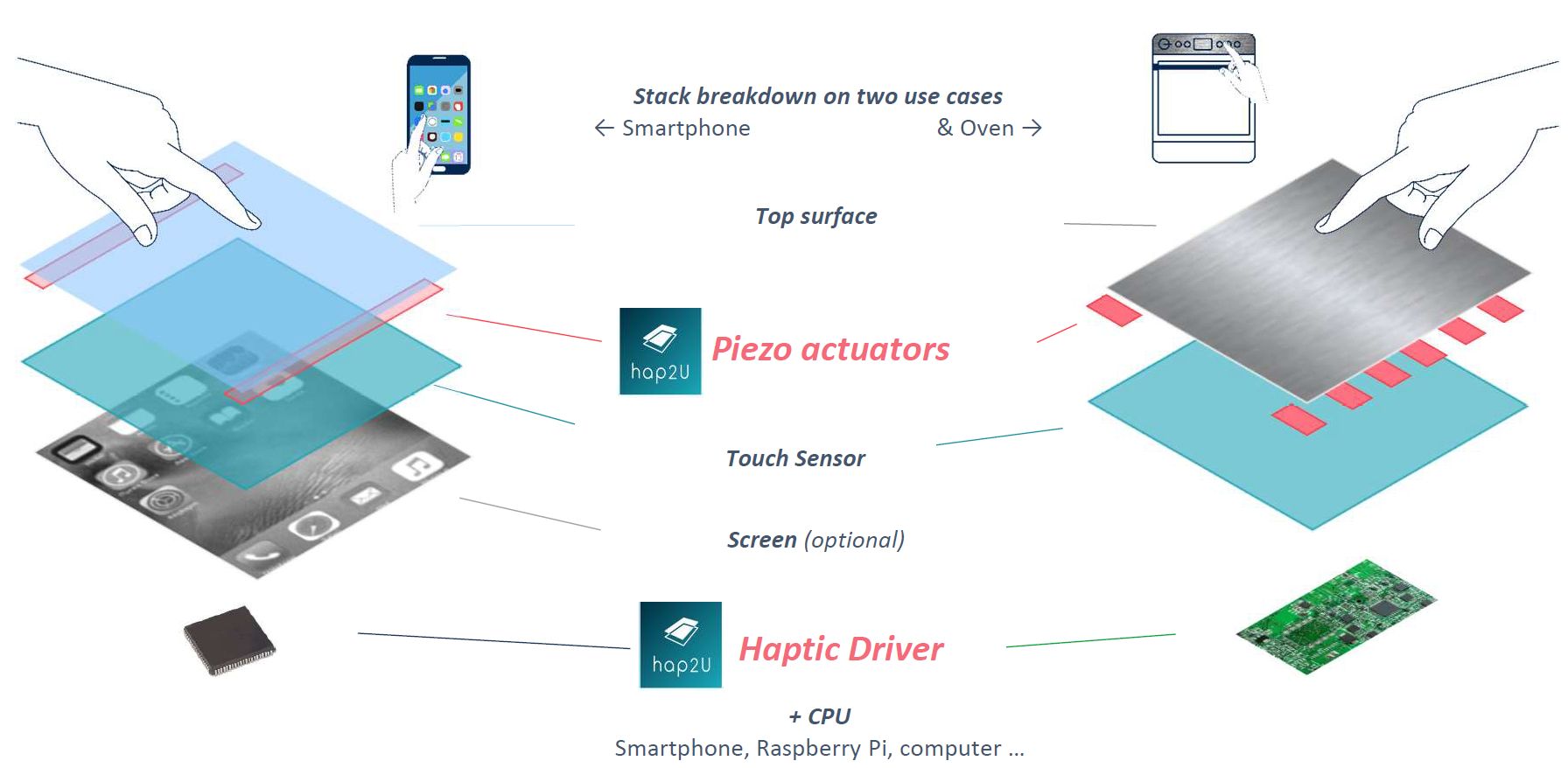

Of course, different materials behave differently when excited by the piezo actuators at tens of kilohertz, and Hap2U has developed the hardware and software know-how to be able to simulate and anticipate both the vibrational and acoustical behaviours of a full mechanical stack. The company’s engineers can then design the optimum piezoelectric layout to get the best mechanical coupling for a given geometry.

“We license all the hardware design know-how, BOM and design as well as the software IP with libraries that enable OEMs to tune the haptic effects for a specific user experience”, said Chappaz. “It wouldn’t make sense to pretend to be a display manufacturer which is very capital intensive” the startup CEO added.

The company has developed a Software Development Kit and some OEMs will build their own touch effects, but some others may ask Hap2U to develop more complex applications for which they may need extra technical support.

Although low cost haptics have been around for years with cheap vibration motors built-in smartphones to silently notify their users of new message, they only deliver a low user experience.

“If you build something that is really useful, then you bring additional value to OEMs. We could bring additional features and remove some of the costs associated with no longer needed hardware”, hinted the CEO when asked if this technology would come at a premium. The impact on display power consumption is minimal, at roughly one per cent. As well as push button feedback, Hap2U supports force feedback on display keyboards, it allows users to feel an object’s contour and texture. The company is confident that what made OEMs so hesitant to implement more complex haptics was the lack of meaningful use cases.

The haptics can be controlled over the full screen, and Hap2U uses the existing capacitive sensors to track finger position and deliver the most realistic haptic feedback. The piezoelectric actuators on the edges can be driven in clusters to independently activate multiple areas of the screen, Chappaz explained.

Again, the effects can be designed to take place across various materials, so the haptic feedback could be implemented on both sides of a smartphone, or on the plastic or metal casing of a white good where the capacitive interface is designed.

In 2018, Daimler AG invested €4M in Hap2U in a A round of funding, looking for new haptic interfaces in future car models and the startup is aiming to raise €50M in B funding in 2020 to focus on the industrialization of its technology for the mass market. The company is recruiting fast, aiming to double its 30 staff to 60 by the end of 2020.

It could take another two to three years to break even, according to the CEO, the time it may require to go to mass production. The Hap2Phone was designed to demonstrate the haptic smartphone display at CES 2020, but the company wants to reach the smart home and smart buildings markets as well as the healthcare and manufacturing industries. With a research partner, Hap2U is currently developing thin film piezoelectric actuators, only 2µm-thick, that could be deposited as a continuous ribbon on glass instead of today’s discrete actuators. The startup already has laboratory samples and is looking for an industrial manufacturing partner to go to mass production.

Hap2U – www.hap2u.net

Related articles:

2D to 3D conversion adds texture on top

Haptics to replace side buttons on smartphones

Augmented reality gets physical with haptics

NXP backs Senseg’s electrostatic touch

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News