How tunable human-centric lighting is placing greater thermal demands on LEDs

For example, in education, a cool blue or white light can help boost students’ (and teachers’) attentiveness after lunch when enthusiasm and energy tend to dip. Conversely, a warmer orange light will help calm a classroom of rowdy children.

In hospitality, restaurants frequently take advantage of basic tunable lighting, creating different ambiences at different times of day for guests — without needing a complex, expensive multimode lighting system.

And in countries that experience extremely high temperatures in the summer particularly the Middle East and extremely low temperatures in the winter, like Switzerland or Canada, more and more buildings feature tunable lighting that offers bluer light in the summer to create a cooler atmosphere and orange light in the winter to create a feeling of warmth.

While the move towards tunable lighting benefits occupants and customers, the technical challenges involved with creating LEDs that deliver tunable lighting is setting LED engineers challenges around cost, performance, reliability and manufacturability.

Turning towards CSP LEDs

To support tunable lighting requires multiple LEDs emitting different wavelengths. This requires many more LEDs in each bulb. One of the essential modifications that engineers must make to the usually deployed standard ‘packaged’ LED is to strip out certain parts to make the LED component smaller, thus creating a chip-scale packaging (CSP) LED where each device is less than 1.2x than its core LED functional element.

Creating a CSP itself is by no means the only challenge — another is how to deal with the intense heat problem caused by the small size. Some CSPs now exceed 10W/mm2. What most engineers know, but consumers do not, is that LEDs tend to be only around 40% efficient, which means the LED wastes 60% of its input power as heat. As with any electronic device, too much heat can negatively affect performance criteria such as light quality and can cause serious damage to the fabric of the LED so needs removing as quickly as possible.

With standard packaged LEDs, removing this heat is a much easier task than with CSPs. Heat cannot escape with through the encapsulant, which is there for protection, so typically it must escape via the back of the LED, travelling through multiple layers of material that spread the heat to mitigate the danger.

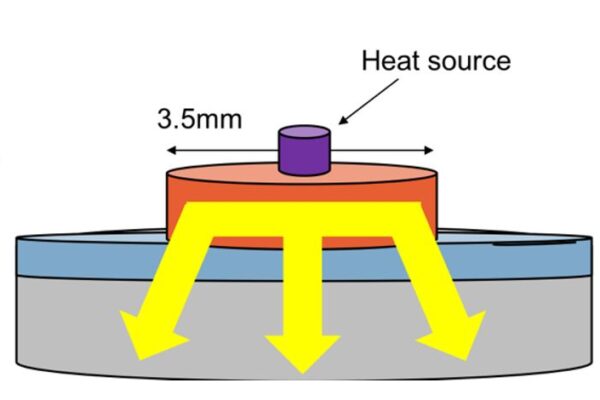

As seen on figure 2, the effect of a sub-mount or package base is to spread the heat from the LED over a larger area before it reaches the metal-clad printed circuit board (MCPCB). This means the MCPCB is not challenged to deal with the cooling the point heat source of the LED junction.

But with CSPs, manufacturers have stripped out the sub-mount or package base (the finished CSP must be no more than 20% larger than the chip itself to qualify as a CSP), which means that the LED now produces the same amount of heat but in a much smaller environment. And as a double whammy, the sub-mount/package base, which the CSP LED has now lost, used to act as a great heat spreader, therefore, reducing the intensity of the heat and the risk. The result is an LED that’s also an intense point heat source that poses risks the light quality and the lifespan of any LED bulb it is added to. And nobody wants to buy a lighting system that doesn’t live up to its full potential.

As shown on figure 3, heat transport though a MCPCB is a combination of radial spreading in the copper and axial conduction through the copper, dielectric and aluminium. To a very simplistic approximation, optimum heat flux is obtained when these vectors are equal. This means if the dielectric of the MCPCB is not a good thermal conductor, then the copper tracking must be 70–105µm thick (2 or 3 Oz) and large in area to provide effective cooling.

A second problem with removing the sub-mount/package base is that it shifts the responsibility of thermal management from the LED packaging manufacturers onto the luminaire integrators and overall light-engine designers. This is something have never had to deal with in their MCPCB solutions up until now.

Traditional CSP thermal management techniques

Traditionally, the only option open to level 2 integrators was to mount the CSP LEDs onto better thermally performing PCBs — usually metal-clad PCBs (MCPCBs) that offer high thermal conductivity. MCPCBs are typically constructed from a solid sheet of aluminium (occasionally copper) usually 1.5mm thick with a 70µm-thin sheet of copper glued on with an epoxy dielectric. This epoxy is often filled with particles of a thermally conductive material like aluminium nitride (AIN) to increase its thermal performance without affecting the electrically isolating properties of the adhesive.

At best, this approach to manufacturing MCPCBs results in a thermal transfer away from these point heat sources of around 100W/mK in the best-performing products — often far less in practice. Whilst this performance is perfectly acceptable for most low-count LED modules the challenge with CSPs is exacerbated by the number of LEDs in close proximity and the way they emit heat. CSPs are a point heat source — their small size mean they quickly saturate any substrate that doesn’t have the requisite thermal conductivity, quickly leaving the LED vulnerable to overheating and failure. There’s clearly a requirement for a more cost-effective board-level thermal management alternative that can deal with the thermal and optical profile of CSPs, while maintaining manufacturability and the ability to use completely standard printed circuit board assembly lines.

MCPCBs at acceptable prices for the first time

Late last year and during January 2018 was a tipping point for the LED industry. Now, there is an alternative to the standard process of creating a metal-clad printed circuit board (MCPCB) — an alternative that used to only be available for high-power LED applications because of its price, but now is affordable for more general tunable lighting thanks to scale of manufacture and years of research and innovation driving down the cost of unit production.

Using an electro-chemical oxidation (ECO) process, Cambridge Nanotherm converts the surface of aluminium into a layer of thermally conductive, but electrically isolating, nano-grain alumina (Al2O3). Because of its method of creation, this “nanoceramic” is atomically bonded to the rest of the board, which very simply provides superior thermal conductivity. While alumina doesn’t necessarily offer the best thermal conductivity as a constituent element, the extreme thinness of the aluminium oxide layer creates results in a thermal resistance from the top side of the copper to the underside of the aluminium of 0.31°C.cm2/W, and potentially lower, which is ideal for tunable lighting, and relaxes design constraints considerably. In simple terms, the best designs can now dissipate heat efficiently enough to allow more individual LEDs to be combined in the same array, increasing tuneable light output without greatly increasing the focal spot size of the bulb.

Figure 4 illustrates how for a standard Nanotherm MCPCB, optimum cooling of a point heat source is achieved by a disc of copper 3.5mm in diameter. While a larger area of copper will help further, the law of diminishing returns applies. Thicker copper is of no benefit (unless the copper area is very large) and increases cost, weight and prohibits circuit tracks with narrow gaps that are essential for connecting to tiny CSP LEDs.

While tunable lighting drives the need for CSP LEDs, its uptake and affordability are being held back by challenges — unless the industry adopts better thermal management. But given the enormous demand for, and potential for, tunable lighting, the LED industry is responding with innovation after innovation. And in this regard, nanoceramic MCPCBs are leading the way.

About the author:

Mike Edwards is VP of sales and marketing at Cambridge Nanotherm – www.camnano.com

Related articles:

The case for nanoceramic PCB in UV LEDs

Startup Nanotherm aims to slash LED lighting heat sink costs by half

Solving CSP LEDs’ thermal challenges

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News