InteGreat project optimizes LED manufacturing

Project partners Osram Opto Semiconductors, Osram, the Fraunhofer Institute for Integrated Systems and Device Technology (IISB), the Fraunhofer Institute for Reliability and Microintegration (IZM), Würth Elektronik, LayTec AG and Mühlbauer GmbH & Co KG investigated new approaches for manufacturing very small surface emitting LED chips and packaging technologies, among other things, as part of the “Photonic Process Chains” initiative. The new insights allow for LED products to be given additional superior properties that would have been difficult or even impossible to achieve with the technologies previously used to produce LEDs.

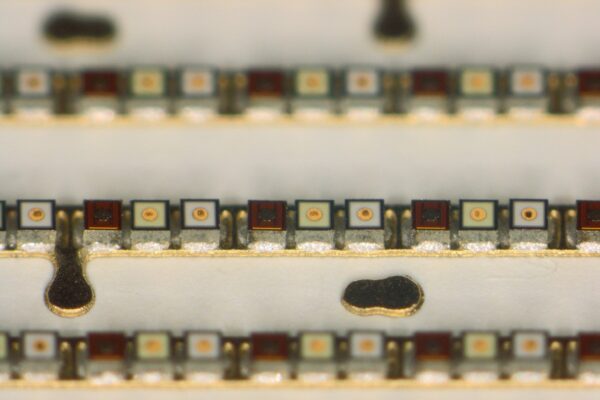

At the heart of the project was wafer level packaging as well as investigations into planar contacts. One of the pioneering approaches to emerge from the project is planar interconnect technology in which the bond wire is replaced by a thin flat metal connection. This moves the surface emitter to the surface of the package. The light can therefore be used more directly, unlike with conventional components. This leads to smaller losses in efficiency and luminance and consequently to greater brilliance and cost savings in operation.

At the heart of the project was wafer level packaging as well as investigations into planar contacts. One of the pioneering approaches to emerge from the project is planar interconnect technology in which the bond wire is replaced by a thin flat metal connection. This moves the surface emitter to the surface of the package. The light can therefore be used more directly, unlike with conventional components. This leads to smaller losses in efficiency and luminance and consequently to greater brilliance and cost savings in operation.

The partners also demonstrated new technologies along the entire value-added chain for functional full-colour video wall modules with a pixel pitch of 1mm.

The results of the project can be applied not only to large-format video walls but also to new applications such as in ambient lighting and sensor systems. Thanks to the modular structure of the project comprising four work packages, many results can now be quickly transferred to product development and production for the accelerated LED integration in industrial applications.

Osram – www.osram.com

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News