New graphene-based recipes spur startups

As a reminder, the Graphene Flagship is one of the largest research projects funded by the European Commission (with a budget of €1 billion over 10 years), it brings together over 150 academic and industrial research groups in 23 countries.

Ever since the first 2D graphene platelets were exfoliated from plain graphite, the wonder material has been tested in all sorts of devices, not only for its peculiar electronic properties but also for its mechanical strength and stability.

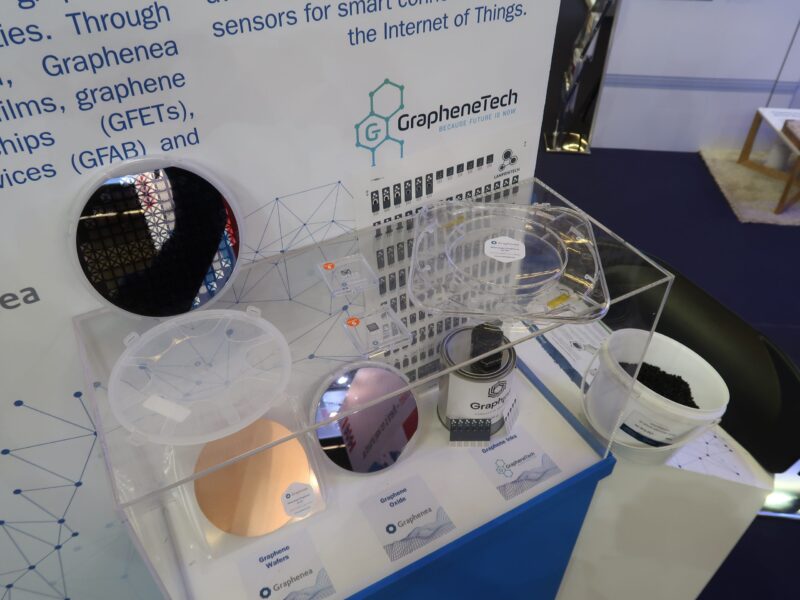

Spain-based industrial-grade graphene provider GrapheneTech was exhibiting various blends of graphene platelets, as powders, mixed into inks for conductive printing or into plastic pellets with various graphene weight percentages for injection molding. On the same stand could be seen 2D graphene monolayers on copper as well as graphene oxide layers on wafers from Graphenea.

based on 2D-layered material.

Project manager at GrapheneTech, José Antonio Peláez Amador walked eeNews Europe through various applications, water-based conductive inks being promising for some printed electronics applications. The company boasts it produces one of the purest graphene in Europe via the solvent-free dry mechanical exfoliation of graphite (an abundant European resource). GrapheneTech also offers its graphene in a wide range of dispersions for functional fluids and coatings.

A surprising example was a car bumper injection-molded from a thermoplastic polymer/graphene nanocomposite, which Antonio Peláez Amador said exhibited improved mechanical properties such as hardness, scratching resistance, tensile strength, while being lighter. Depending on the added graphene weight percentages and how they are processed, resins can become thermally and electrically conductive while benefiting from enhanced mechanical properties. Dispersed into rubber, graphene not only improves the material’s structural stability and impact resistance, it brings it triboelectric properties too, which could be of interest to tyre manufacturers.

Graphene even gets mixed into cement, turning the building material into what the HeidelbergCement group calls a cementitious conductive layer, used both as cement for bedding tiles and as a cheap heating resistor layer that provides floor heating at the same time. A demonstrator showed electricity conduction through the graphene-laden cement, heating up a tile above. A poster anticipated house-wide applications such as wall heating, outdoor de-icing, but also electromagnetic interference shielding, all structurally integrated.

On the electronics side, the Catalan Institute of Nanoscience and Nanotechnology (ICN2) was exhibiting a large area electroluminescent gas detector capable of providing local visual cues (lighting up progressively) upon gas and humidity detection, in real time. For humidity detection, just exhaling towards the sensor film created a diffuse luminous reaction across the sensor-equipped screen-printed electroluminescent display. The thin screen-printed displays contains a layer of a graphene oxide nanocomposite which becomes conductive in response to certain changes in the air composition, locally turning on the electroluminescent display while maintaining a direct relationship between light intensity and the conductivity.

local visual cues of humidity presence.

Ruslan Álvarez, researcher at ICN2 explained eeNews Europe such reactive displays could be built to be invisible in the absence of detection (in airplaines, cars, hotel rooms or at home) but emit a clear visual signal in case of a particular gas detection. ICN2 has worked on a humidity sensor but is also working on the detection of different gases including for the medical market. One application could include breath detection and the intensity of breathing cycles, Álvarez noted. Such displays could be produced cheaply and could be functionalized to respond with light to gases such as CO, CO2 or NO and possibly other contaminants.

On the sensing front, Raivo Jaaniso, Head of the Laboratory of Sensor Technologies at the University of Tartu (Estonia) leveraged the high sensitivity of single-atomic-layer graphene’s conductivity to defects and doping to create ultra-sensitive gas sensors through localized functionalization. “They are based on a small matrix of chemiresistive graphene sensors, functionalised with small amounts of metal oxides or precious metals”, Jaaniso explained, referring to a recently published paper in Applied Physics Letters, “Highly sensitive NO2 sensors by pulsed laser deposition on graphene”.

The paper describes how graphene can be functionalized to create adsorption centres of different types for target gases by so-called pulsed laser deposition (PLD), introducing locally and very precisely small amounts of materials onto pristine graphene. Using Ag and ZrO2 as the deposition material, the researchers were able to multiply the response to NO2 gas in air by 40 times in the case of PLD-modified graphene, in comparison with pristine graphene, reaching 7 to 8% at 40 ppb of NO2 and 20 to 30% at 1 ppm of the noxious gas. Many different gas sensors could be designed on a tiny sensor as the precise PLD tool can form a variety of defects or clusters on graphene from different atomic species with different “landing energies”, explains the paper, typically impacting under 1% of a monolayer’s through a single laser pulse.

They also found that signal recovery times and sensitivity at low concentrations could be further improved under UV light, extrapolating a level of detection as low as 1 ppb for NO2 (from a few to a few hundreds of ppbs). Jaaniso anticipates that with further research and investment, such sensors could be integrated into mobile phones to actively monitor toxic substances in the ambient air.

Technologies holding sole-shaped screen-

printed graphene-based force sensors.

Another interesting demo was that of a capacitive-based pressure/force sensor demonstrated by Dr Yarjan Abdul Samad, research associate at the Cambridge Graphene Centre. By screen-printing graphene on both sides of a thin transparent plastic film, Samad and his team have developed cheap and flexible capacitive-based force sensors that could be used embedded in soles for running or gaming applications, but also for medical applications such as gait analysis. Here the demonstration consisted of a snowboarding video game where the player’s avatar (leaning forwards or sideways while surfing in snowy curves) could entirely be controlled through sensor-equipped shoes.

Heading up the startup Camsmart Technologies recently spun-off Cambridge University, improvised CEO Samad aims to commercialise the sensors. The startup is seeking partners to develop new solutions on a project basis, creating a library of designs and IP to address different market segments including industrial, medical and gaming.

MEMS from Atomic Mechanics.

Founded in 2017, Manchester-based startup Atomic Mechanics was here to promote fully transparent flexible and stretchable graphene-polymer films turned into organic MEMS (Micro Electromechanical Systems) to create force-touch sensitive interfaces. Described as MEMS-TI, the MEMS consist of polymer-supported conductive graphene films freely suspended over a cavity. When a pressure is applied to the film, deformation of the graphene inward the cavity can be measured through the change of its electrical properties. But the same pressure/force sensor could be driven electrically as an actuator for haptic applications, claims the company on its website.

between taps and taps with maintained pressure.

The startup expects to be able to manufacture such MEMS devices in large quantities at a competitive price point. It wants to offer large-area transparent force/touch sensor arrays as interface overlays for screens of all sizes, possibly including haptic feedback all in one layer, with a high spatial resolution. Atomic Mechanics didn’t want to leak any specs yet but is working on a commercial release soon.

GrapheneTech S.L. – www.graphene-tech.net

ICN2 – www.icn2.cat

Cambridge University – www.cam.ac.uk

University of Tartu – www.ut.ee

Atomic Mechanics – www.atomic-mechanics.com

The Graphene Flagship – www.graphene-flagship.eu

Related articles:

European graphene initiative doubles its size with new funding

Building flexible microprocessors from 2D-material transistors

Phosphorous tipped as 2D 5nm transistor material

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News