Photovoltaic-operated thin film electronic ion pumps for implants

Operating on the principle of selective electrophoretic ion transport from a source solution to a target solution across an ion exchange membrane, an electronic ion pump is a device that allows the precise and convection-free delivery of small-sized ionic species. By applying an electric field along the membrane, specific ions are transported from one end to the other with a negligible amount of solvent being co-transported with the ions.

Thus far, thin organic electronic ion pumps (OEIP) have been used in vivo to modulate sensory functions through electrophoretic drug delivery, or to alleviate epileptic seizures through the local delivery of neurotransmitters. But all implementations reported in literature relied on external power supplies (hence wiring), which increases the chances of inflammation, especially for long-term therapy applications.

In a paper titled “Wireless organic electronic ion pumps driven by photovoltaics” published in Nature’s journal of Flexible Electronics, the researchers report a thin OEIP coupled to an organic photovoltaic (OPV) driver, on a flexible carrier. The whole implant can be addressed by red light within the tissue transparency window, removing the need for external wiring.

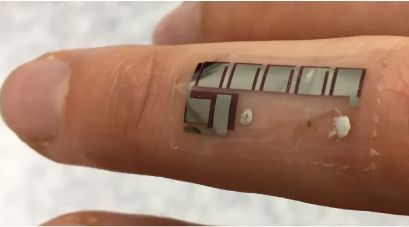

organic photovoltaics, adhered on the skin.

In order to obtain the 2.5–4.5 V necessary for operating the high-resistance electrophoretic ion pumps, the researchers arranged organic thin-film bilayer photovoltaic pixels in series and in vertical tandem. To prove the concept, they laminated the device onto a finger and were able to drive it with a red LED emitting through the finger’s thickness.

As the authors explain, the OPV active material was chosen to strongly absorb red light in the tissue transparency window (600–700 nm), and by virtue of their high absorption coefficient materials, could be designed to a thickness under 300 nm so the overall implant thickness could be minimized while remaining flexible.

Linköping University – https://liu.se

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News