Tech trends in the lab: Apps displace buttons, GPIB lives on

There are more or less two reasons why lab instruments become more user-friendly: First, many systems have reached the physical limits to further improve test accuracy and sensitivity – once a ampere meter can measure in the attoampere range (10 by the power of minus 18), it does not make much sense to further increase the sensitivity, Bachmayr said in an interview with eeNews Europe. As a consequence, manufacturers seek to differentiate themselves through better and more intuitive user guidance.

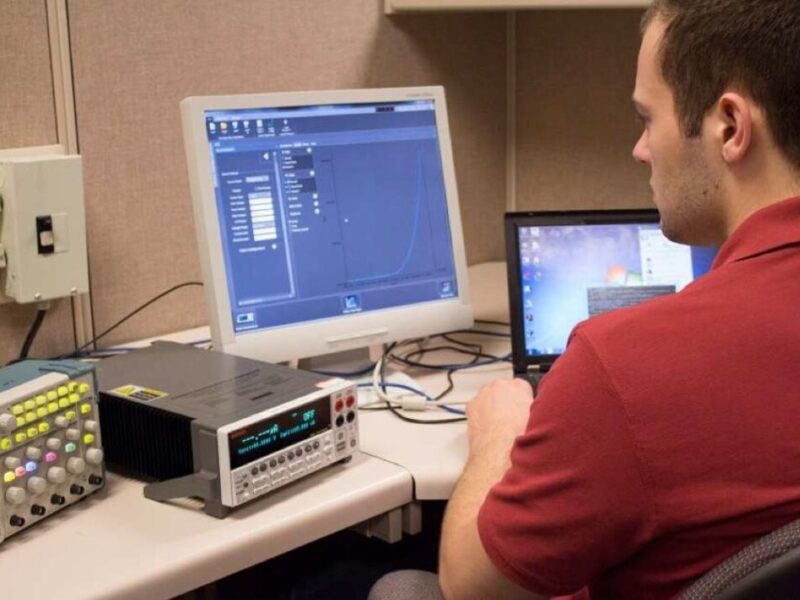

There is indeed a necessity to implement ease usage and provide HMI concepts that can be understood also by non-experts. "Today, new groups of users are getting into contact even with sophisticated measurement equipment", Bachmayr said. Whereas in earlier times only development engineers, in some cases even particularly qualified test engineers were using the instruments, the situation has changed significantly: Measurement instruments are increasingly entering new environments beyond electronics development laboratories and manufacturing test sites. Today, measurements are performed in many sciences from physics to biology, chemistry, medicine and more. For this reason, measurement instrument designers cannot anticipate that all users are experts; and hence they need to simplify the use of even sophisticated instruments. As a result, future instrument generations will feature context-sensitive and more comfortable user interfaces. Instrument designers take up user interface trends from the IT and consumer markets – instead of a dedicated display screen at the instrument, the screens of PC monitors and tablet computers are utilised to display measurement results from a simple voltage value to complex FFT results. In some cases, even a smartphone app is available to enable a user to watch the measurements on his mobile phone. "There is a clear trend towards ‘app-ification’ of measurements", Bachmayr explained.

This trend does not end in simply allowing external display devices to access the measurement instrument. The next logical step is embedding the measurement results into a web site and accessing them with a standard web browser. This enables remote measurement applications: In field service and maintenance situations, the service local engineer can call in an expert from the development department to resolve tricky problems. "Through these technologies, instrument manufacturers can cut their time-to-market for new products", says Bachmayr.

Not only user expectations undergo a constant change. So does the demand. Based in Munich, Germany, for Keithley EMEA the automotive industry is a very significant customer, and the ‘electronification’ of the car generates significant demand from car suppliers developing electronic solutions for vehicles. And the trend towards green automobility is reflected in the demand for instrumentation: High voltage (because electric cars are powered by high voltage batteries) and low power are the most significant usage trends, acknowledges Bachmayr.

A major demand driver is the connected car. Infotainment, radar, car-to-x communications – all these applications determine the demand for test and measurement equipment. "RF Interferences are a dramatic topic", Bachmayr said. "In particular it drives the demand for real-time spectrum analysis".

Another big issue for measurement technology is, of course, the Internet of Things (IoT). In this context, the challenges lie in the ability to measure ultra-low currents. "Since these intelligent sensors typically are powered by batteries, they must be designed to consume very low power", the Keithley expert says. The quiescent current of MCUs in intelligent sensors frequently lies in the area of femtoamps and the measurement equipment has to take these requirements into account.

In power electronics, semiconductor manufacturers are about to evaluate next-gen materials such as GaN or SiC. While the design of such devices reflects the demand from customers in the automotive industry, the customers for equipment to characterise GaN and SiC devices are in the semiconductor industry. "In the characterisation of these transistors existing equipment hits its limits", Bachmayr explains. The faster switching speed translates into higher bandwidth requirements, and since GaN and SiC transistors are handling much higher power levels, users need meters, oscilloscopes and source measure units need to cover the kilovolt and tens of amperes range – "albeit not necessarily at the same time", as Bachmayr puts it.

And, finally, has the time come to pronounce the General-Purpose Interface Bus (GPIB) death, as some observers are saying? "This is something I hear since 20 years", Bachmayr explains. "But if you listen to the customers, it is alive and well, and it will live on for decades." Nevertheless, alternatives to the venerable data bus, a development of HP back in the sixties, are looming. "Ethernet would be a good candidate, in particular in connection with LXI. And also USB is gaining significance".

Related articles:

A Dragon Fruit for test and measurement: Red Pitaya comes to Europe

Power wafer-level testing and automated characterization

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News