Until Micro LEDs get ready, Mini LEDs market is set to expand, says LEDinside

Companies can develop Mini LED using their current equipment, with only small changes of manufacturing process.

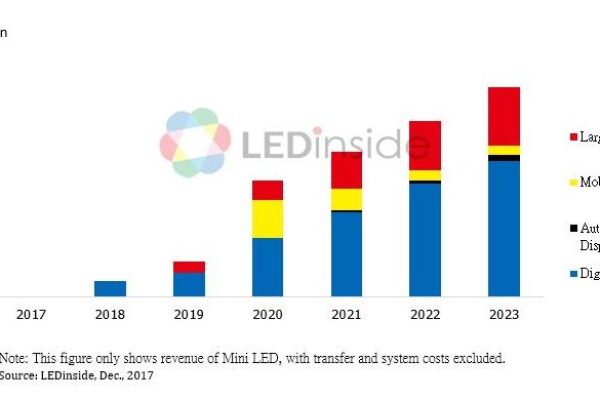

According to the market research firm, Mini LEDs have the potential to be adopted for television, mobile phones, automotive display, digital display, etc., with revenue expected to reach US$1 billion in 2023. In particular, LED digital displays and large-size TVs will be the mainstream applications of Mini LEDs.

With sizes of about 100-200μm, mini LED chips can be used both for self-emitting displays and backlighting, notes Simon Yang, Assistant Research Manager of LEDinside.

Sony has released a Micro LED display in 2016, which had a rather high cost and technological barrier, so LED companies now turn their research on Mini LEDs, which have a larger chip size, for realizing mass production in shorter time. Compared with traditional LED displays, Mini LED displays are more likely to have a high dynamic range imaging and a wider colour gamut too.

For consumer electronics products, the cost of using Mini LED chips for a self-emitting display is too high, and the resolution may not meet the requirements of existing products. Therefore, companies aim to use Mini LED as backlight to replace traditional backlighting in LCD panel. Mini LED backlighting can be used in TVs, mobile phones, automotive displays, etc.

LEDinside estimates that Mini LED backlighting demos are likely to be released in 2018.

High-end TV products may be able to adopt Mini LEDs, with a high brightness and higher dynamic range imaging. In terms of applications in mobile phones, Mini LED-equipped products could realize a high contrast and high brightness similar to OLED products. Together with local dimming, Mini LEDs are likely to compete with OLED in terms of performance and price.

Companies worldwide have been actively involved in the development of Mini LED products, including chip makers like Epistar, Lextar, San’an Optoelectronics, HC SemiTek, etc., packaging companies like Everlight, Advanced Optoelectronic Technology, Harvatek, Seoul Semiconductor, etc., IC designers like Macroblock, Raydium, etc., panel makers like AU Optronics, and Innolux Corporation, and digital display makers like Leyard, etc.

However, there are still challenges for the development of Mini LEDs. Their high cost is a major concern since Mini LED product uses more chips, leading to higher costs in pick and place and bonding processes, as well as longer processing time and higher risks of low yields. In addition, Mini LEDs need more optical distance, which adds to the difficulty in making thin products.

LEDinside – www.ledinside.com

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News