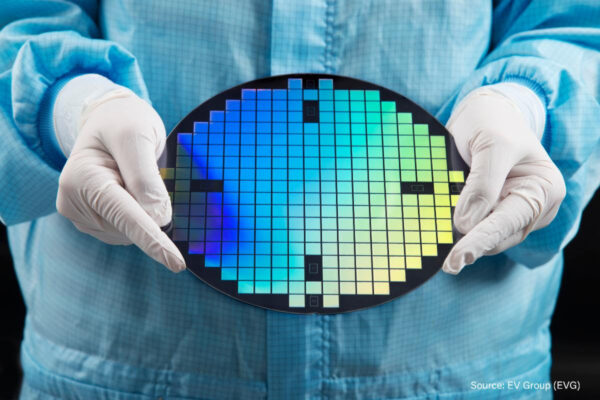

EVG and Inktron partner on novel materials for diffractive optics

These DOE structures (diffractive optics) include waveguides for augmented/mixed/virtual reality (AR/MR/VR) devices, as well as beam splitters and diffusers for advanced optical sensing used in automotive, consumer electronic and commercial applications. This partnership is being carried out within EVG’s NILPhotonics Competence Center at its headquarters in St. Florian, Austria. EVG’s NILPhotonics Competence Center provides an open access innovation incubator for customers and partners across the NIL supply chain to collaborate to shorten development cycles and time to market for innovative photonic devices and applications.

As part of this agreement, Inkron has also purchased an EVG 7200 NIL system for use in its own research and development facility to accelerate the development and qualification of new optical materials. The EVG 7200 system leverages EVG’s innovative SmartNIL technology and materials expertise to enable mass manufacturing of micro- and nanoscale structures as small as 30 nm over a large area with unmatched low-force and conformal imprinting, fast high-power exposure and smooth stamp detachment.

“Demand for wafer-based optical components and sensors across commercial and consumer markets is accelerating at a breakneck pace, driving the need for materials and processes that are optimized to meet the performance requirements and production volumes required in these markets,” commented Markus Wimplinger, corporate technology development and IP director at

EV Group.

“Inkron has extensive know-how in optical materials, and is one of the leading manufacturers of high and low RI coatings, making the company an ideal partner to work with at our NILPhotonics Competence Center. Collaborations such as this one enable EVG to further explore and expand the applications and capabilities of our NIL technology, ensuring the availability of production-ready solutions for next-generation optical devices and end products.”

The material properties of optical elements and components have a major impact on the overall performance and form factor of the packaged optical device. For example, higher refractive indices (up to 1.9x and above) enable optimized designs for improved outcoupling of the light, which can significantly increase the field of view of waveguides, providing a more immersive experience in AR/VR headsets. Higher RI materials can also provide higher optical density and enable more efficient diffractive optics used for beam splitting (such as for facial recognition sensors), supporting further miniaturization of the optics. Additional optimization of high RI materials can provide better contrast due to improved film transparency as well as reduced haze and scattering, while improved resin stability can address more stringent thermal requirements, such as those needed in automotive applications.

Optimizing the high RI materials for NIL processing helps ensure their implementation in volume production. NIL is a proven method for manufacturing optical elements due to its ability to provide cost-effective patterning of nanometer-scale features at high volume, while being insensitive to feature size, shape and complexity.

EVG – www.evgroup.com

Inkron – www.inkron.com

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News