Andy MacInnes, chief development officer of Paragraf Ltd. (Somersham, England), discusses the next steps for the UK developer of graphene electronics.

Andrew MacInnes, chief development officer, Paragraf Ltd.

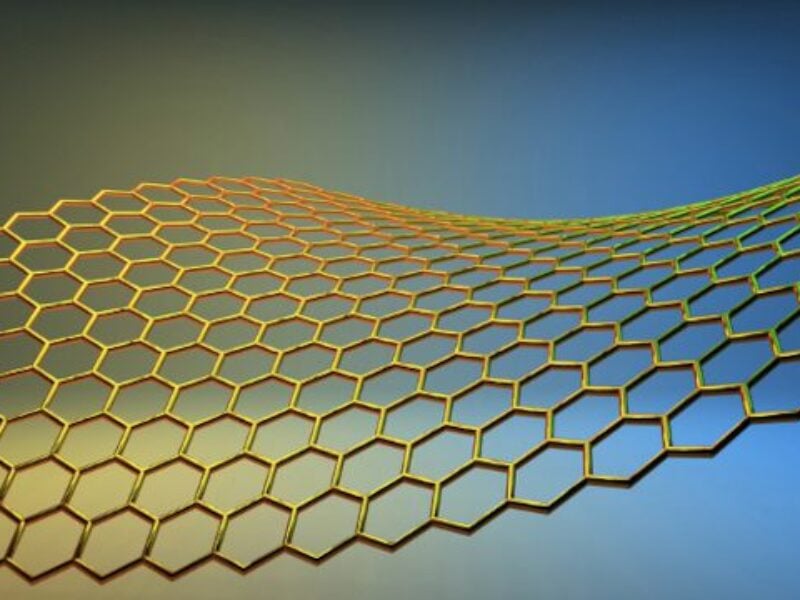

Graphene is a single atomic layer material that holds the promise to produce devices and components with market-leading specifications. Paragraf’s position is based on its ability to lay down contamination-free graphene without the use of a copper catalyst. Paragraf’s techniques has already produced chemical and magnetic sensors with enhanced sensitivity and could be extended to produce graphene-based transistors superior to silicon equivalents.

The company is approaching its ninth birthday and has a couple of products in the market, a Hall-effect sensor of exceptional sensitivity and a graphene FET (GFET) that can be used for molecular sensing in biological, health, agricultural and other applications. The molecular sensor comes courtesy of Paragraf’s acquisition of Cardea Bio Inc. in May 2023 (see Graphene pioneer Paragraf acquires bio-sensor startup Cardea).

CEO interview: Building a graphene industry, one layer at a time

MacInnes said Paragraf’s Hall-effect sensor has potential in automotive applications and in quantum computing but he admits graphene electronics, “has not really gained traction in the market yet.” As chief development officer it would seem to be MacInnes job to help make that happen.

“I worked at TriQuint Semiconductor in the 1990s, now part of Qorvo, on gallium arsenide. Back then gallium-arsenide was always the technology of the future. It’s future never seemed to arrive but eventually gallium arsenide found market entry in the communications domain,” said MacInnes.

“That’s where graphene is right now. Automotive has a strict and lengthy qualification process so adoption into volume production will take some time,” he added.

Automotive applications include battery management systems where Paragraf’s sensors can be used to monitor individual battery cells, operating accurately over broad temperature ranges. The same sensors, which in essence link voltage, current and magnetic field strength, can be used for steer-by-wire systems. Here the advantage is a high signal-to-noise ratio over a broad dynamic and temperature range. Conventional Hall-effect sensors are already in use here but graphene-based devices have the opportunity to reduce the number of components required, MacInnes said.

“But it’s got to prove itself,” said MacInnes. “We’ve got to start delivering the widgets that applications need.”

Quantum computing

“In quantum computing it’s not the same challenge. There isn’t an established qualification process and its more of a blank canvas. Here the cryogenic capabilities of graphene mean it can measure magnetic fields at milliKelvin temperatures,” MacInnes said.

He explained that for many approaches to quantum computing it is necessary to subtract stray magnetic fields at temperatures near absolute zero as part of the method of detecting the quantum state of qubits. “We are sampling products. It’s a niche area where we have traction and we are gaining a lot of learning.” In this case the market is more immediate but it is essentially one of relatively high value but low volume.

And then there are the molecular sensors. “We’ve opted to sell the GFET base unit and allow customers and third parties develop the intermediate layers used to capture a specific molecule such as methane or biological markers,” said MacInnes. He pointed out that in the area of health applications there are long and expensive qualification processes that the company has opted not to take on.

At the same time Paragraf remains committed to researching devices aimed at other applications that can take advantage of graphene’s 2D-material characteristics. Here the challenges may come from how to transfer the mono-layer graphene into part-processed devices, said MacInnes. “We probably need to grow the graphene in situ; to grow-in the quality,” he said.

This background – and the fact that Paragraf took possession of a 43,000 square feet manufacturing site in Huntingdon in February 2023 – points to Paragraf being a manufacturing company (Paragraf opens second UK graphene electronics manufacturing site).

Make first, license later

“The general concept right now is that we have to develop our own standard products to establish the market for graphene electronics,” said MacInnes. “We have a development fab and we will be in Huntingdon soon to allow general manufacturing. We do expect to outgrow the Huntingdon site. At that point we would be better placed to license the process to other foundries.”

MacInnes added that the pathway depends on the degree of maturity of the process. “The back-end, packaging, we already out-source,” he added.

But being a manufacturing company also means that Paragraf needs funds for capital expenditure. The company closed a Series B round of financing worth US$60 million in 2022 (see Paragraf raises $60 million for graphene).

In Paragraf’s full accounts for the year ending December 31, 2022, which were signed off on June 2, 2023, it was stated that the company was engaged in a Series C round of venture capital financing that was expected to complete in the coming months. MacInnes did not comment on this except to agree further funding is necessary to propel Paragraf forward. “If we were a fabless chip company it would different, but we are not,” he said.

As a pioneer of the graphene electronics sector Paragraf is carrying a lot of expectations and the possibility of long-term returns on its shoulders. The size of that Series C – and how soon it is announced – will be an indication of how aggressively Paragraf can engage in the next phase of its development.

Related links and articles:

News articles:

Paragraf opens second UK graphene electronics manufacturing site

Black Semi raises €250 million for graphene pilot wafer fab

Paragraf raises $60 million for graphene

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News