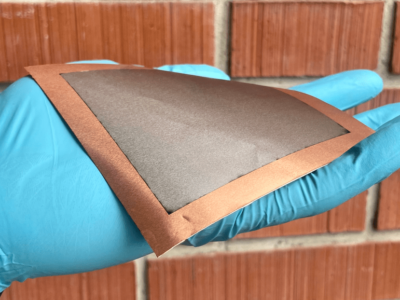

Solid state electrolyte for silicon battery

Silicon battery technology and solid state electrolytes are two areas of particular interest to provide safer batteries with higher energy densities, and there are many companies and research labs wokring on both.

The team at the US Army Research Laboratory and the University of Maryland have used a solid electrolyte to address some of the challenges of silicon battery cell design and provide a longer lifetime with higher energy density.

“We are very excited to demonstrate a new electrolyte design for lithium ion batteries that improves anode capacity by more than five times compared to traditional methods,” said Army scientist Dr. Oleg Borodin. “This is the next step needed to move this technology closer to commercialization.”

The team designed a self-healing, protective layer in the battery that significantly slows down the electrolyte and silicon anode degradation process which could extend the lifespan of next generation lithium-ion batteries.

Their latest battery design increased the number of possible cycles from tens to over a hundred with little degradation and was published in Nature Energy.

Anodes made out of silicon can offer about 1,500 to 2,800 mAh/g, four times as much capacity as the graphite anodes used in today’s lithium ion cells.

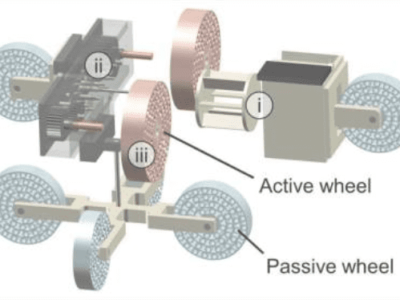

Silicon expands and contracts during a battery’s operation, and as the silicon nanoparticles within the anode get larger, they often crack the protective layer — called the solid electrolyte interphase — that surrounds the anode.

The solid electrolyte interphase forms naturally when anode particles make direct contact with the electrolyte. The resulting barrier prevents further reactions from occurring and separates the anode from the electrolyte. But when this protective layer becomes damaged, the newly exposed anode particles will react continuously with electrolyte until it runs out.

“Others have tried to tackle this problem by designing a protective layer that expands when the silicon anode does,” Borodin said. “However, these methods still cause some electrolyte degradation, which significantly shortens the lifetime of the anode and the battery.”

Instead, the joint team at the University of Maryland and the Army Research Laboratory designed a rigid barrier that doesn’t break apart, even when the silicon nanoparticles expand. They developed a lithium-ion battery with an electrolyte that formed a rigid Lithium Fluoride solid electrolyte interphase, or SEI, when electrolyte interacts with the silicon anode particles and substantially reduced electrolyte degradation.

“We successfully avoided the SEI damage by forming a ceramic SEI that has a low affinity to the lithiated silicon particles, so that the lithiated silicon can relocate at the interface during volume change without damaging the SEI,” said Prof. Chunsheng Wang, a professor of Chemical and Biomolecular Engineering at the University of Maryland. “The electrolyte design principle is universal for all alloy anodes and opens a new opportunity to develop high-energy batteries.”

The battery design showed a coulombic efficiency of 99.9 percent, which meant that only 0.1 percent of the energy was lost to electrolyte degradation each cycle. This is a significant improvement over conventional designs for lithium-ion batteries with silicon anodes, which have a 99.5-percent efficiency. This translates to a cycle life more than five times longer says Borodin.

“Experiments performed by Dr. Chunsheng Wang’s group at the University of Maryland showed that this new method was successful,” Borodin said. “However, it was successful not only for silicon but also for aluminium and bismuth anodes, which shows the universality of the principle.”

The silicon battery design also came with several other benefits. The higher capacity allowed the electrode to be markedly thinner, which made the charging time much faster and battery itself much lighter. In addition, the researchers found that the battery could handle colder temperatures better than normal batteries.

“For regular batteries, colder temperatures slow diffusion and may even freeze the liquids inside the batteries,” said Borodin. “But because our design has a much higher capacity, thus ions have to diffuse shorter distances, resulting in a significantly improved low temperature operation.”

The next step in the research is to develop a larger cell with a higher voltage using this design and improving the commercial LiFePO4 and Lithium/Nickel/Colbalt/Aluminium cathodes in the design.

Related silicon battery articles

- STARTUP RAISES $45M FOR US PRODUCTION

- HYBRID SILICON CARBON ANODE FOR SOLID STATE LITHIUM BATTERY

- CARBON SILICON ANODE GIVES FOUR TIMES CAPACITY BATTERY BOOST

- SPHERICAL GRAPHITE BOOST FOR SILICON ANODE BATTERY TECHNOLOGY

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News