£10m to commercialise long range EV batteries

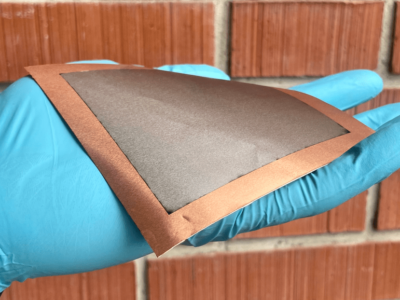

Silicon battery pioneer Nexeon is heading up a £1.5m (€2m) project to develop batteries with longer range for electric vehicles with manufacturing startup BritishVolt and the UK Battery Industrialisation Centre.

The Silicon Anode Battery for Rapid Electrification (SABRE) project will develop battery cells with higher energy density than today’s lithium ion cells. This follows the Sunrise project in 2018 that was developing silicon materials for a battery with a range of 400 miles.

Related articles

- Wacker takes stake in UK silicon battery maker Nexeon

- Nexeon Raises £30 million for Next Generation Li-ion Batteries

- Nexeon acquires 24 key battery patents

- UK project to double range of electric vehicle

The SABRE project will use the new cell assembly capabilities at UKBIC for the fabrication of 21700 cells to test and validate the new cell design. Nexeon will work with Britishvolt and University College London (UCL) to deliver test cells with a combination of advanced Li-ion cell design and novel silicon anode material over the next year.

This will build on decades of development at Nexeon on silicon anode materials, already shown to improve the performance of Li-ion batteries. Silicon has a greater affinity for lithium than graphite, and this enables the production of cells with increased energy density. Nexeon’s silicon material design is achieving a combination of high lithium capacity with low volume change for long cycle life.

In the SABRE project, Britishvolt will use computer-aided cell design and simulation to accelerate the integration of silicon into the anode design. These tasks will be supported by UCL’s Electrochemical Innovation Lab.

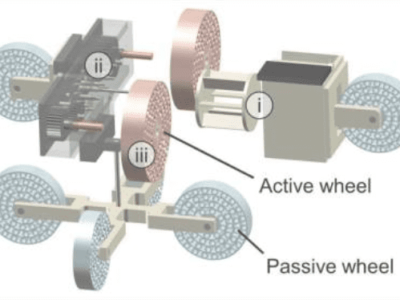

BristishVolt is also leading another project called GENESIS (Generating Energetic Novel cells and Systems Inspired by Software) that aims to design and demonstrate a large format lithium-ion pouch cell.

This will be optimised to deliver both high energy density and sustain fast charging to the automotive sector technical requirements and use-case specifications, provided by an automaker. The consortium will integrate both high energy cathode materials and novel separator technology from project partners Johnson Matthey and ENTEK Membranes. Prototype cells will be fabricated to refine and validate the modelling undertaken at Imperial.

“We are very excited to lead this important work, and to collaborate with our partners in designing and producing higher performance battery cells,” said Dr Scott Brown, CEO of Nexeon. “This project, and others like it, are important in building a UK-based lithium ion battery capability, and reducing risk in an increasingly competitive supply chain.”

“This is a very exciting work stream and will allow the development of market leading products as we progress on our roadmap to building the UK’s first full-scale Gigaplant,” said Craig Chapling, R+D Programme Manager at Britishvolt. “Collaboration is at the very core of our business model, and this project is another example of our ability to partner for success.”

“The Electrochemical Innovation Lab at UCL is delighted to partner with Nexeon and Britishvolt to translate our cutting-edge research to accelerate the development of advanced batteries to support the transition to net zero,, said Professor Paul Shearing from UCL Chemical Engineering.

This is part of further investment of £10 million from the Faraday Battery Challenge to support collaborative R&D projects

Two separate projects build on the success of researchers at Imperial College London working on the Faraday Institution’s Multi-scale Modelling project and its subsequent Industry Sprint TOPBAT. The team has previously demonstrated significant opportunities for improvements in energy density at pack level, lifetime and cost optimising cell design for thermal management rather than exclusively for cell-level energy density, as is current industry practice.

The Power-Up project will establish the feasibility of manufacturing AMTE Power’s Ultra High Power cells in the UK, at volume. The aim is to have an automotive format cell ready for production at UKBIC by the end of the 12-month project. AMTE will engage with potential UK customers for these cells, providing them early mover advantage.

HIPERCARB (High performance hard carbon composites for Na-ion) builds on an existing relationship between the NEXGENNA project and one of its industry partners Deregallera and preliminary data generated by a Faraday Institution cohort PhD researcher at Lancaster University. HIPERCARB will screen composites based on hard carbons manufactured by Deregallera for use as possible anodes for sodium-ion batteries, optimising them to reduce cost and targeting an improvement in cell level energy density over 200Wh/kg, a step beyond current state-of-the-art, leading to the manufacture and testing of a pouch cell using the most promising anode material.

www.nexeon.com; www.britishvolt.com;

Other articles on eeNews Power

- My battery is bigger than yours

- Deal targets 200kW wireless charging road technology

- Reducing the temperature of molten sodium batteries

- ChargePoint to buy has·to·be for $250m

- Pilot for UK national EV charging uses smart meter network

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News