3D manufacturing process enables more rational electronics production

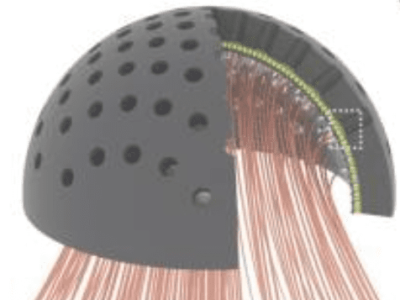

Why do electronic components always have to be soldered to a printed circuit board? Couldn’t these components be integrated directly into the chip housing instead? Tobias Tiedje, a scientist at the Technical University of Dresden, asked this question. With his team, the scientists developed a manufacturing approach that saves around half of the usual process and design steps and at the same time better copes with the current challenges of high data transmission, cooling and miniaturization. The most varied types of components and molded parts as well as structures (cavities and microchannels) can be used. They called their new technology KONEKT (“Contacting of embedded components as a technology solution”).

KONEKT revolutionizes the production of electronic and microtechnical assemblies by using 3D manufacturing technology. The aim is to combine the advantages of mass production with the flexibility of individual production. Simplified processes enable fast and automated production of optimized assemblies through the high-frequency connection of the respective components. At the same time, process, energy and material costs are significantly lower.

This gives medium-sized companies in particular the opportunity to establish new business fields through rapid electronic manufacturing or the production of individual assemblies without high set-up costs. “With KONEKT, a wide variety of products can be realized in production,” explains team leader Tobias Tiedje. “From 3D sensor assemblies as prototypes to RFID and high-frequency assemblies in series for the Internet of Things (IoT). The new technology offers users many design options without restricting their creativity”.

The team around KONEKT was able to raise 807,000 euros in funding from the Federal Ministry of Economics and Energy and the European Social Fund as part of the EXIST programme. Now the foundation of an independent company is on the agenda to enable the future production of adaptively manufactured 3D assemblies in market-ready sizes and to offer small and medium-sized companies “packaging as a service”.

More information: www.iavt.de/konekt

Related articles:

Mentor: An intelligent DFM approach to PCB manufacturing

In-Mold Electronics: the transition from art to platform technology

Quality control plastics injection molding process optimization software

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News