Learning connector lessons with single pair Ethernet

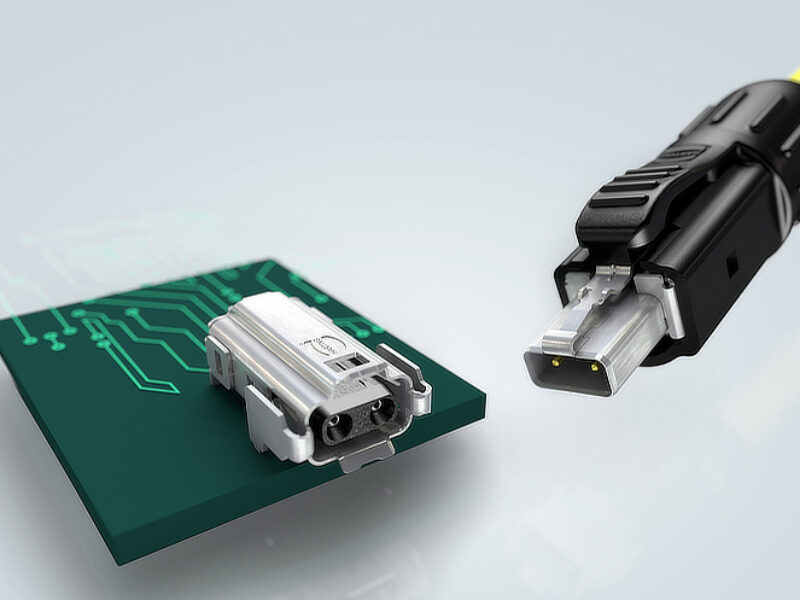

A new standard for single pair Ethernet (SPE) is gathering speed with multiple companies joining the SPE industrial partner network to avoid making the same mistakes as the past with prorietary connector systems.

A new standard for single pair Ethernet (SPE) is gathering speed with multiple companies joining the SPE industrial partner network to avoid making the same mistakes as the past with prorietary connector systems.

The partner network, based in Rahden, Westphalia, Germany, started with HARTING, TE Connectivity, HIROSE, Würth Elektronik, LEONI, Murrelektronik and Softing IT Networks, and now includes companies such as Molex, Amphenol ICC and Lütze alongside seven others.

Molex is taking a broader view of the technology as a key element for the next generation of connected industrial and factory automation systems as part of Industry 4.0, starting in Europe. It want to move away from being a connector supplier to a system consultant.

“I think Europe is probably ahead, and probably the first massive adopter considering the players here,” said Riky Comini, Global Director of Industrial Automation at Molex (left). Comini is responsible for product management, business development and engineering globally.

“The Molex position is we have learned a very good lesson from the past and we are using that experience to collaborate with a series of players that are going to drive something good for the customer and for the market,” he said. “Most of the development for networks in general has been fragmented.”

He points to the Molex Ultra-Lock connector system for networking. “Ultra-Lock was invented in 2000 and presented to the market but the fact that we kept it closed meant the industry struggled with adoption,” he said. “We have all these connectors but if the market isn’t going to adopt it there’s no point.”

So the international specification of IEC 63171-6 for SPE and multiple companies with the same interface for connectors and a common form factor is a new way of approaching the market. “This gave us good inroads into understanding the market,” he said. “It’s a multi-source connector but the adoption will be much higher.”

Next: Wider engagement through single pair Ethernet

He see Molex as having an advantage with the rest of the network specifically in industrial automation rather than other areas such as avionics with single pair Ethernet. “Within Molex you only see the connector but we also have a cable manufacturer. Molex acquired Flamar not to lower the cost of cables with vertical integration but to bring technology,” he said. “In industrial automation the most important thing is not only the IP rating but working in different environments such as welding with an outer jacket or with cutting oil, so for high flex, welding resistant, oil resistant cables, Flama is equipped to do that.”

Molex aims to bring together multiple elements of single pair Ethernet for customers in industrial automation and robotics, he says. “For us it’s not just SPE, it’s the power supply, switch, I/O block, HMI, sensor, vision system so end-to-end means going from the power to the IO blocks which will no longer have simple single functionality but have multiple functionality and the ability to add features, different languages,” he said.

“There is roadmap for connectors, collaboration with other players and cable specifications and we have submitted prototype and sample for connectors and cables.” This is intended to persuade system makers to adopt the technology.

“Some of the players will use a company they have been using for many years but while the market is evolving there are companies emerging with completely different solutions. With Industry 4.0 the idea was to open up the platform and have open sourcing to go to the next level of communication,” he added.

“Molex is coming out with a complete solution for Industry 4.0 trying to design an end-to-end solution where SPE is a key differentiator – we are going for machine builders and robotic companies,” he said. This includes automotive automation, food and beverage manufacture, material handling and fulfilment centres.

“The major change we made was to experiment with the customer rather than presenting a complete idea to the market,” he said. “We want to be no longer a supplier of bits and pieces but a consultant.”

“You can have all the device manufactures with SPE but if the machine builders and customers don’t adopt it, it will take longer to be adopted,” he said. “So we are trying to select specific early adopters and use a machine builder in Japan and see how they can bring it into their system, from the simple communications cable to sensors communicating directly, then other devices can be added. It is creating a demo line for a major automotive manufacturer for a complete system eliminating the cabinet,” he said.

“Based on my experience of 32 years in the connector industry, in about a year people will start adopting it but the industrial market will see larger adoption that is meaningful for the user in perhaps three years,” he said.

However Molex is still looking at producing its own version that includes power to simplify the connections to sensors and smart connected I/O blocks. “We can bring a hybrid version with higher power,” he said, “as well as dual pair hybrid connectors with two or four power wires.”

Molex will have parts coming to market later this year and through 2021, even considering the impact of the Covid-19 pandemic, but the major changes will happen the following year. “2022 is when we see the change to the smart I/O block that today has a dual pair ethernet. That block is changing with a different power connector so we want to arrive with SPE and then with smart I/O block,” he said.

www.molex.com; www.single-pair-ethernet.com/

Related articles

- SPE MOVES INTO AIRCRAFT DESIGNS

- HARTING AIMS RECTANGULAR CONNECTOR AT INDUSTRIAL ETHERNET

- FILTER DESIGN TARGETS SPE INTERFACE

- FIRST COAXPRESS 2.0 INTERFACE CHIP FOR IMAGING

Other articles on eeNews Europe

- Complete audio system opens up A2B bus

- Covid-19 lessons for leading chipmakers

- €1bn deal for graphene battery that charges in 15s

- ON Semi looks for its next CEO

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News