Coiled carbon nanotube yarn harvests energy under strain

Publishing their findings in Science in a paper titled “Harvesting electrical energy from carbon nanotube yarn twist”, the researchers reported unprecedented energy outputs per weight with CNT yarns twisted to a point they would completely coil then dipping them into an aqueous electrolyte.

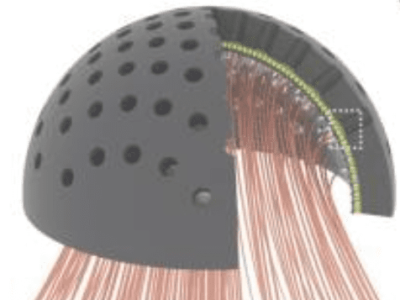

nanotube yarns. Source – University of Texas at Dallas.

Under strain, the CNT yarn harvesters electrochemically convert tensile or torsional mechanical energy into electrical energy, without requiring an external bias voltage. Stretching these coiled yarns generated up to 250 watts per kilogram of peak electrical power when cycled up to 30 hertz, as well as up to 41.2 joules per kilogram of electrical energy per mechanical cycle, when normalized to harvester yarn weight.

characterization of harvester yarns: consisting of a

coiled MWNT yarn working electrode, a high-surface-

area counter electrode, and a reference electrode,

all immersed in a aqueous electrolyte.

The yarns behave like variable supercapacitors whose energy density changes under tensile strain (the fibres get closer and so the charges from the impregnating ionic liquid). A single electrochemical cell consists of a coiled MWCNT yarn working electrode and a high-surface-area counter electrode, both immersed in an aqueous electrolyte (essentially see water for their ocean energy-harvesting demonstration).

twistron ocean-wave harvester for wave frequencies

of 0.9 to 1.2Hz. The harvester was tethered to the

ocean floor and mechanically limited to under 25%

stretch.

To prove the worth of their coiled twisted CNT yarn as energy harvesters, the researchers tested it in several configurations, including a 10cm-long 1.08mg twistron ocean-wave harvester tethered to the ocean floor and mechanically pulled by a floating balloon at the frequency of passing waves, between 0.9 and 1.2Hz. The device yielded a peak-to-peak open-circuit voltage of 46mV and an average power of 1.79mW. Normalized to the harvester electrode weight, the average output power through a 25-ohm load resistor was 1.66W/kg.

With a slight modification, the twistron was also implemented into fabrics, overcoating the coiled CNT yarn with a gel electrolyte and helically wrapping a non-coiled, twisted CNT yarn counter electrode coated with an ionically conducting hydrogel.

Protected with a PVA/HCl gel electrolyte, the combined two-electrode assembly was used as a thread sewn into a knitted cotton glove, further overcoated with a PVA/LiCl gel electrolyte. Several such threads were knitted, connected in parallel and in series, generating sufficient power as the textile was stretched up to 50% to power small wearable sensors.

peak short-circuit current (SCC) at 1Hz and 50% strain

for series (black squares) and parallel (blue circles)

connected harvesters using homochiral and

heterochiral yarn pairs. The yarns were coated with a

10–wt % PVA/4.5 M LiCl gel electrolyte after being sewn

into a textile.

When combined in series, such harvester yarns can provide arbitrarily high voltages, alternatively, their voltage can be up-converted using commercially available circuits.

The paper cites an example where the 80mV output voltage of a single coiled harvester electrode, weighing only 0.019g, charged a 5mF capacitor to 2.8V using a voltage step-up converter. This was enough to power a green LED each time the harvester yarn was stretched.

According to Dr. Ray Baughman, director of the NanoTech Institute and a corresponding author of the study, although numerous alternative harvesters have been investigated for many decades, no other reported harvester provides such high electrical power or energy output per cycle as the twistron for stretching rates varying from a few cycles per second to 600 cycles per second.

The University of Texas at Dallas has filled a patent application jointly with Hanyang University and the technology is available for licensing.

University of Texas at Dallas – www.utdallas.edu

Hanyang – Hanyang University – www.hanyang.ac.kr

Related articles:

Woven piezoelectric yarns lead to 3D textile energy harvester

Energy-smart textile combines photovoltaics and energy storage

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News